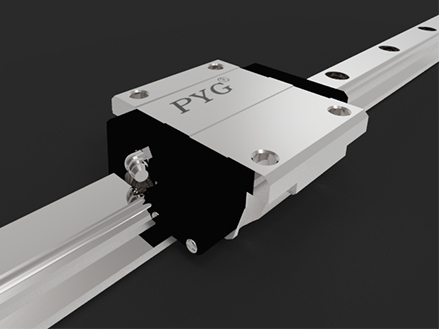

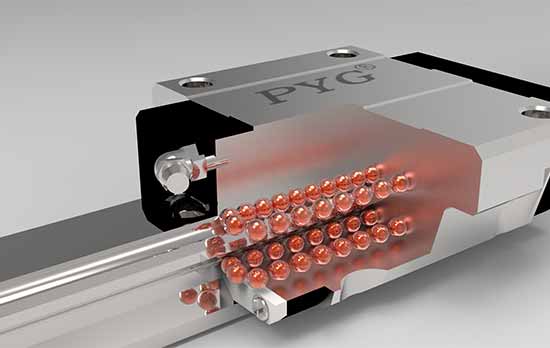

Ball type series linear slide rail

The four column single arc tooth contact linear guide rail, combined with the optimized structural design of the ultra heavy load precision linear guide rail, has improved load and rigidity capabilities compared to other linear guides; Equipped with four directional load characteristics and automatic centering function, it can absorb assembly errors on the installation surface and achieve high-precision requirements.

(1) Automatic centering ability

The DF (45 ° -45 °) combination from the circular groove, during installation, can be absorbed by the linear guide rail through the elastic deformation of the steel ball and the transfer of the contact point. Even if there is some deviation in the installation surface, it can produce the effect of automatic centering ability and achieve high-precision and stable smooth motion.

(2) Interchangeability

Due to strict control over production and manufacturing accuracy, the size of linear slides can be maintained within a certain level, and the slider is designed with retainers to prevent steel balls from falling off. Therefore, some series of accuracies are interchangeable,

Customers can purchase slides or sliders as needed, and they can also store slides and sliders separately to reduce storage space.

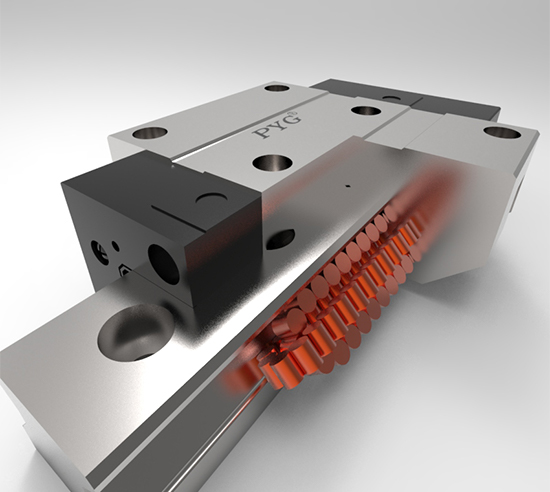

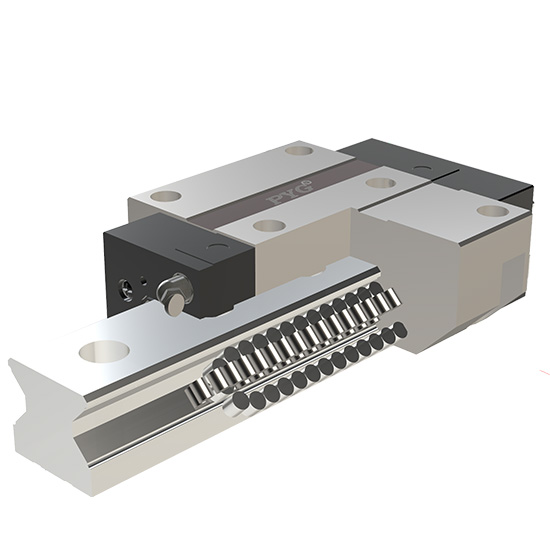

Roller series linear guide rail

Replacing steel balls with roller type rolling elements, designed to achieve ultra-high rigidity and overload capacity; By using the line contact method between the rolling element and the sliding rail and slider, the rolling element only forms when subjected to high loads. The trace amount of elastic deformation, coupled with the design of a 45 degree contact angle, enables the overall linear slider to achieve the characteristics of equal rigidity and load capacity in all directions. By achieving ultra-high rigidity, machining accuracy can be greatly improved to meet the demand for high precision; Due to the characteristics of overloading, the service life of linear slides is extended. Very suitable for high-speed automation industry machinery and equipment with high rigidity requirements.

(1) Optimal design

The reflux module of the roller series linear guide ensures that the roller type rolling elements can smoothly perform infinite cyclic rolling. And use advanced finite element method for structural stress analysis to determine the optimal design of the slider and slide rail structure.

(2) Extend lifespan

The roller series linear slide rail is based on the IS014728-1 specification to develop the basic dynamic rated load, which is calculated based on a rated life of 100 kilometers. The lifespan of a linear guide rail may vary depending on the actual working load it is subjected to. The lifespan of a roller type linear guide rail can be calculated based on the basic dynamic rated load and working load of the selected linear guide rail.

At present, PYG ball circulation guideways have been supplied in bulk to enterprises' automated production lines, achieving dual standards of "high speed+precision"; The roller circulation guideway has become a core supplier for heavy equipment manufacturers, playing a high rigidity advantage in machine tool spindle feed and rail transportation equipment debugging.

With the upgrade of precision manufacturing to "customization", PYG is developing a lightweight version for roller modules and adding dust-proof and wear-resistant components to them, further breaking the traditional application boundaries.

Post time: Jul-23-2025