In the field of automation and precision manufacturing, the ball-type linear guide rail is like a low-key yet crucial "unsung hero". With its outstanding performance, it lays a solid foundation for the accurate and stable operation of various equipment.

All-round Dust Prevention, Protecting the Core of Precision Transmission

The all-round dust-proof design of the ball-type linear guide rail is a key line of defense to ensure its long-term stable operation. At the groove where the guide rail and the slider are connected, high-density dust-proof scrapers and sealing strips are built-in, and together with the double-block external dust-proof structure, a 360° dead-angle-free dust-proof system is constructed. Whether it is fine dust in the production environment or particle impurities under complex working conditions, it is difficult to invade the interior of the guide rail. This design can effectively avoid the wear and interference of dust on precision components such as balls and guide rail raceways, so that the guide rail always maintains good transmission accuracy and smoothness, and prolongs the service life. It is especially suitable for industrial scenarios with more dust, such as automation devices supporting woodworking machinery and mining equipment.

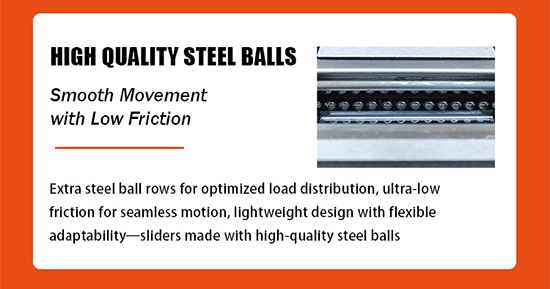

High-quality Steel Balls, Achieving Smooth and Low-friction Movement

The high-quality steel balls it uses are the core elements to achieve smooth and low-friction movement. The additionally configured steel ball rows are optimized to achieve uniform distribution of loads, so that the guide rail can maintain a stable stress state when bearing loads in different directions and sizes. At the same time, the guide rail adopts a lightweight and flexible structural design, and the ultra-low friction characteristics between the steel balls and the raceways make the slider feel almost no resistance when moving. This feature allows the equipment to move smoothly like flowing clouds and water during operation, whether it is high-speed reciprocating or low-speed fine movements, which greatly improves production efficiency and processing accuracy. Precision machine tool feed systems, electronic component placement equipment, etc. all benefit from this feature.

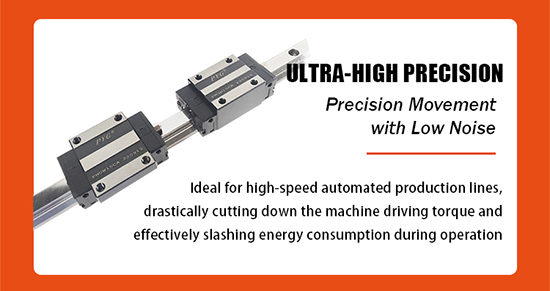

Ultra-high Precision, Facilitating Low-noise and Efficient Production

The ultra-high-precision movement performance of the ball-type linear guide rail is fully demonstrated in high-speed automated production lines. It can provide equipment with millimeter-level or even more precise positioning accuracy to meet the needs of high-precision processing and assembly. At the same time, the low-noise operation performance makes the production line bid farewell to harsh friction noise and creates a more comfortable production environment. More importantly, its low-torque feature greatly reduces the energy consumption when the equipment is driven. While saving energy and protecting the environment, it also reduces equipment loss. It is very suitable for high-speed automated production fields such as automobile manufacturing and 3C electronics that have strict requirements on speed, precision, and energy consumption.

The ball-type linear guide rail, with advantages such as all-round dust prevention, smooth low friction, ultra-high precision and low noise, has become a core transmission component of many precision equipment and automated production lines, promoting the modern manufacturing industry to move towards a more efficient and more precise direction.

Post time: Sep-15-2025