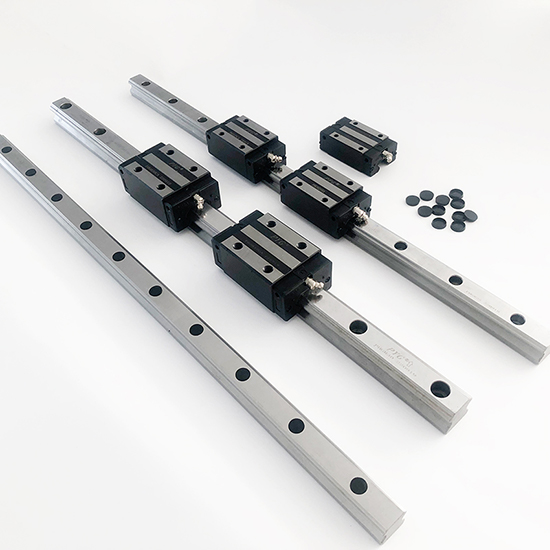

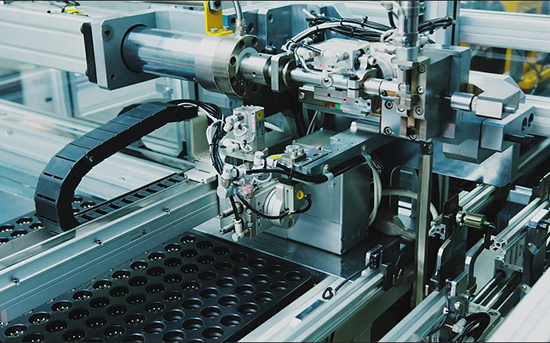

Electronics Manufacturing Industry: Reliance on Precision Assembly

Electronic components are small and precise, allowing no margin for error in assembly and welding. On electronic automated production lines, linear guide rails can achieve a repeat positioning accuracy of ±0.001mm, making electronic component welding more precise and reducing defect rates. For equipment like lithography machines and wafer inspection devices used in chip manufacturing, which require nanometer-level displacement accuracy, linear guide rails can stably control the movement of components, ensuring that chip manufacturing processes meet standards and helping electronic enterprises overcome precision challenges in high-end equipment production.

Machine Tool Industry: Core for Enhancing Machine Performance

Machine tools are the "processing workhorses" of the manufacturing industry, and their performance depends entirely on precision and efficiency. High-performance linear guide rails can reduce the friction coefficient of machine tools, minimize mechanical wear, and extend equipment service life. When high-end CNC machine tools process complex parts, their high rigidity and fast response capabilities enable the machines to maintain stability during high-speed cutting, improving processing precision and surface finish. This helps machine tools upgrade from "ordinary processing" to "precision manufacturing," meeting the processing needs of complex components across various industries.

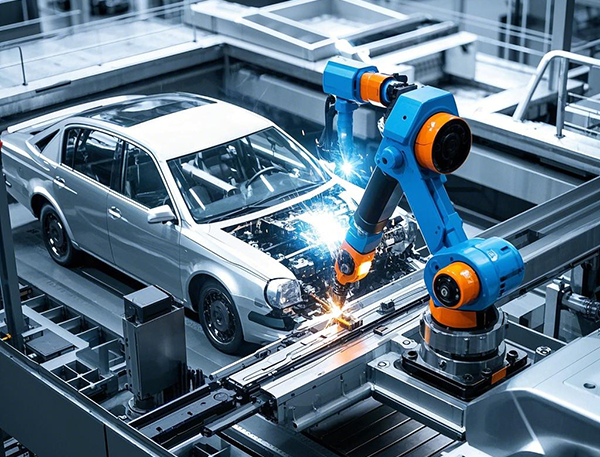

Automotive Manufacturing Industry: Adapting to Automation and New Energy Production

Automotive production lines feature a high degree of automation, and welding robots and assembly robotic arms all rely on linear guide rails for precise positioning. Linear guide rails ensure the consistency of body welding and component assembly, reducing errors. For new energy vehicles, linear guide rails can also be adapted to scenarios such as battery PACK assembly and precision motor processing. They can not only withstand heavy loads but also operate stably in complex environments, helping automotive enterprises improve production efficiency while meeting the higher precision requirements for components in new energy vehicles.

Medical Equipment Industry: Safeguarding Diagnostic and Therapeutic Precision

The precision of medical equipment is directly related to patients' health, and linear guide rails play an important role in this field. In CT scanners and MRI equipment, they drive the stable movement of detection components, ensuring clear imaging and accurate data. Surgical robots rely on them to achieve millimeter-level or even sub-millimeter-level motion control, making minimally invasive surgeries more precise and safe, reducing surgical risks, and promoting the development of medical equipment toward higher precision and intelligence.

Post time: Aug-28-2025