Linear Guides: The "Precision Guidance Core" for Machine Tool Motion

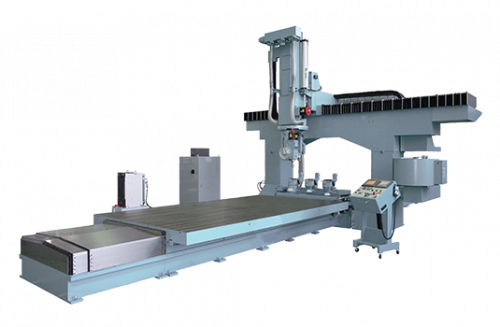

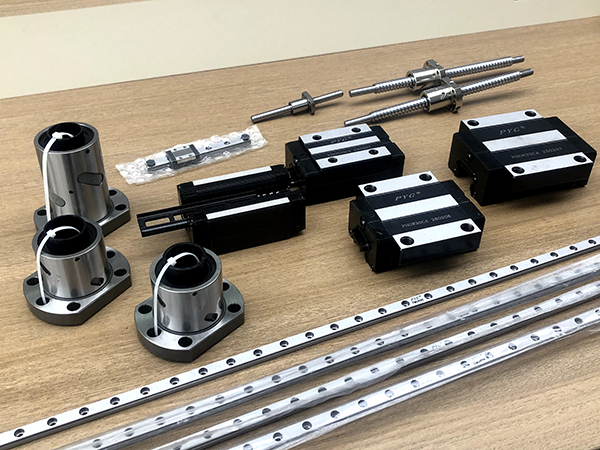

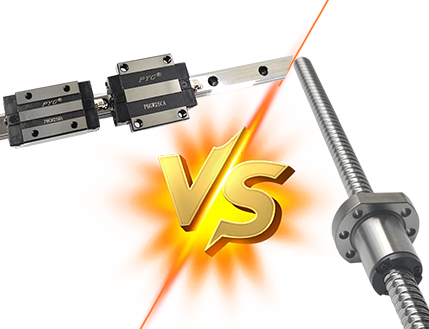

As the "core framework" for linear motion in automated machine tools, the technical performance of linear guides directly determines the upper limit of machining precision. They are applied in key motion areas of machine tools and adopt differentiated designs based on specific scenarios:

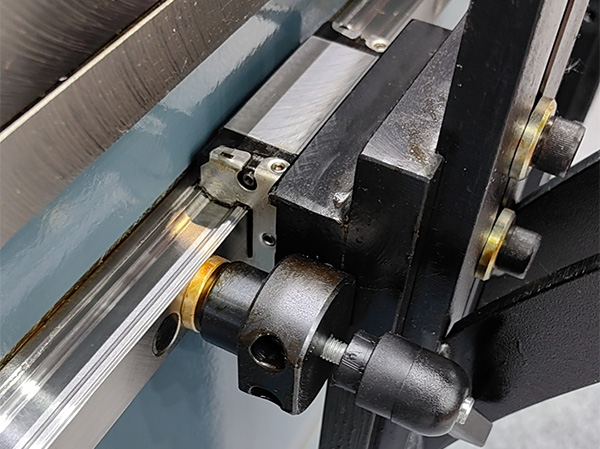

Workpiece Table Area: Heavy-duty linear guides are mostly used here, with a symmetrical layout of double guide rails. The guide rails are made of high-hardness alloy steel and undergo ultra-precision grinding, resulting in a surface roughness of ≤Ra0.1μm. The fitting clearance between the guide rails and sliders can be adjusted to within 0.002mm through preloading. When processing large-sized workpieces, these guides can evenly distribute the load, prevent deformation of the worktable, and ensure that the straightness error of the workpiece movement is ≤0.005mm/m, eliminating deviations from the source.

Processing Head Movement Area: High-precision miniature linear guides are used here. The cross-section of the guide rails mostly adopts a four-row ball circulation structure, which can evenly bear loads from multiple directions. When the processing head needs high-frequency fine adjustments, it can rely on the low-friction rolling of the balls to shorten the positioning response time to within 0.1 seconds and control the displacement precision at the micrometer level, helping to achieve a mirror-like machining effect (e.g., Ra0.02μm).

In addition, linear guides are generally equipped with self-lubricating systems and dust-proof sealing structures. The self-lubricating system injects special grease at regular intervals and in fixed quantities to reduce wear and extend service life; the dust-proof sealing (such as organ-type protective covers) can block metal chips and dust, preventing precision from being affected by contamination.

Ball Screws: The "Precision Transmission Assistant" for Key Parts

Ball screws are mainly used for the feed drive of the machine tool's processing head, and their core function is to accurately convert the rotational motion of the motor into linear motion. They consist of a screw shaft, a nut, and internal balls. Through the cyclic rolling of the balls, low-friction transmission is achieved, with a friction coefficient only 1/30 of that of traditional sliding screws. This can reduce energy consumption, minimize heat generation, and avoid precision drift caused by temperature changes. During processing, the feed depth can be controlled according to instructions, with a minimum feed rate of 0.001mm, ensuring that the processing parameters accurately match the requirements.

For manufacturing enterprises, the quality of core components such as LM Guide directly determines production efficiency. For example, in the auto parts industry, machine tools using high-precision guides can increase the workpiece processing qualification rate to over 99.5% and reduce equipment failure rates by 40%. In the field of medical device manufacturing, relying on the micrometer-level precision of machine tools, enterprises can meet the strict requirements for surface finish and dimensions of high-end devices, helping to break through technical barriers in overseas markets.

With the advancement of Industry 4.0, linear guides are developing in a more intelligent direction. Some high-end machine tool models have integrated temperature and vibration sensors into the guides, which can monitor the operating status in real time and upload data to cloud platforms. These systems can provide early warnings of abnormalities and push maintenance recommendations, realizing "predictive maintenance" and preventing production interruptions caused by sudden failures, thus providing support for the high-quality development of the manufacturing industry.

Post time: Sep-02-2025