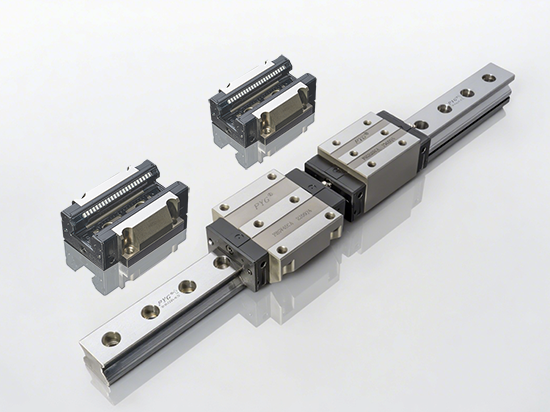

Accuracy classes hinge on five key characteristics: height tolerance of rail and block assemblies, height differences between multiple blocks on one rail, width tolerance, width differences between blocks on a rail, and parallelism between rail and block reference edges. These factors directly impact stability and precision in operation.

Selection depends on mounting configurations. For a single block on one linear rail, height and width tolerances matter most, with accuracy needs tied to application positioning requirements—rigid tooling or tight payload positioning demands higher classes like P or SP.When multiple blocks share a rail, height and width differences become critical. Uneven dimensions cause uneven loading, risking premature failure. Here, higher classes (H or above) are advisable to ensure balanced stress distribution.

The common setup of two parallel rails with two blocks each requires aligning six components. While "super" precision isn’t always needed, High (H) or higher classes are recommended to manage combined tolerances of height, width, and parallelism. Beyond setup, application specifics matter. CNC machining or precision measurement demands SP/UP classes, while general uses may suffice with C or H. Longer travel distances, harsh environments, and heavy loads also push the need for tighter tolerances to minimize deviations and stress.

In essence, choosing linear guide accuracy balances application needs, mounting setups, and operational conditions. Matching the right class to these factors ensures both performance and cost-effectiveness in precision systems.

Post time: Jul-31-2025