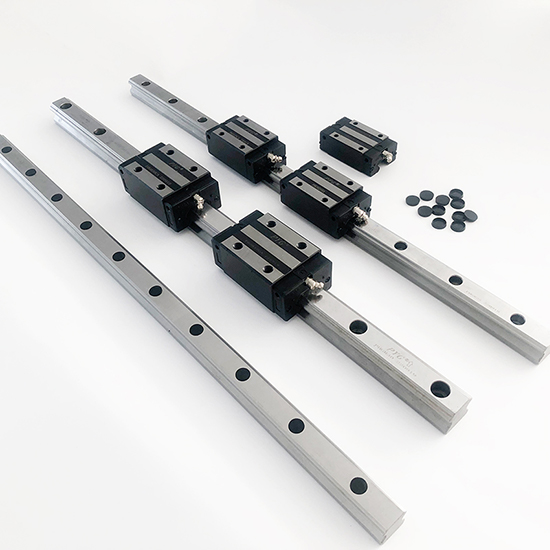

PYG linear guide rails are made of carefully selected S55C steel as the raw material. This steel has excellent comprehensive mechanical properties, laying a solid foundation for product quality. During the production process, it undergoes a series of precise processes, including quenching, cutting, shaping, surface anti-rust treatment, grinding, and inspection. The quenching process significantly increases the surface hardness of the guide rails, enhancing their wear resistance; precise cutting and shaping ensure accurate product dimensions; the surface anti-rust treatment effectively extends the service life of the guide rails, enabling stable operation even in harsh environments; the meticulous grinding process is the key to achieving ultra-high precision. Through fine polishing of the guide rail surface, the surface roughness is reduced to an extremely low level, providing a guarantee for high-precision movement.

Strict inspection processes are integrated throughout the entire production process. Every stage, from raw materials to semi-finished products and finally to finished products, undergoes multi-dimensional inspections. It is precisely with this persistent pursuit of craftsmanship that PYG linear guide rails achieve ultra-high precision, with a maximum travel accuracy of ≤ 0.003mm, far exceeding the industry average. This enables them to meet the requirements of equipment with extremely high precision requirements, such as high-end CNC machine tools and precision measuring instruments.

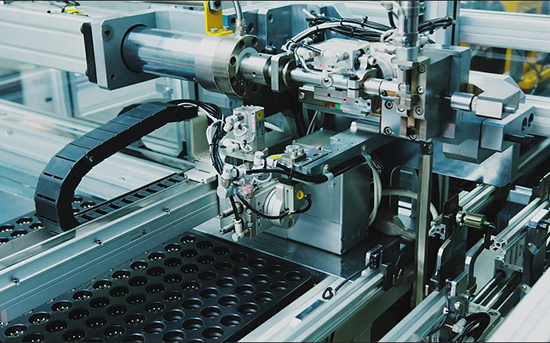

In addition to high precision, PYG linear guide rails also have the significant advantage of a long and reliable service life. Every step, from material selection to processing, fully considers the durability of the product. They can still operate stably under harsh working conditions such as high loads and frequent start-stops, significantly reducing equipment maintenance costs and downtime. Their high dust-proof ability is also outstanding. Special structural designs and protective measures can effectively prevent the intrusion of impurities such as dust and debris, ensuring normal operation in dusty environments.

For extreme environments such as high temperatures and vacuum, PYG has launched guide rail models made entirely of metal. The all-metal material is not prone to deformation at high temperatures and can meet the special requirements of vacuum environments, providing reliable solutions for fields such as semiconductor manufacturing and aerospace.

Post time: May-13-2025