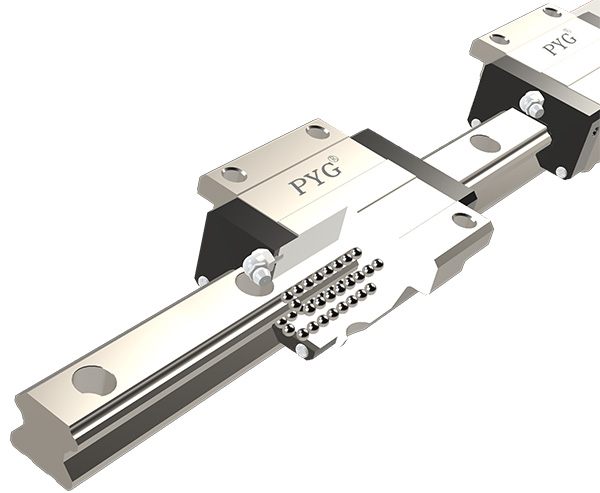

PYG linear guideways begin with meticulous raw material selection, specifically choosing high-quality S55C medium-carbon steel. Renowned for its excellent comprehensive mechanical properties and machinability, this steel lays a solid foundation for high-quality guideways. Workers carefully inspect the surfaces of guideways and sliders, ensuring no rust, deformation, or pits. The straightness of the guideways is measured with a feeler gauge, keeping the twist within ≤0.15mm. A hardness tester is used to precisely achieve a hardness of HRC60±2. Micrometers and calipers are employed to control the dimensional errors of guideway cross-sections and sliders within ±0.05mm. These procedures fully leverage the superior characteristics of S55C steel, strengthening the foundation for top-tier guideways.

Once the raw materials pass inspection, the true "tempering journey" commences. In the surface grinding process, linear guideways are placed on a workbench, fixed by a magnetic chuck, and leveled before grinding the bottom surface. The surface roughness is reduced to ≤0.005mm, achieving mirror-like precision. Meanwhile, the sliders undergo precision milling of their cross-sections on a milling machine, with angular tolerances strictly controlled within ±0.03mm, ensuring precise compatibility with the guideways.

During the critical stage of guideway and slider milling, PYG uses specialized grinding machines to grind the three-sided raceways of the guideways. The width tolerance of the raceways is controlled within ±0.002mm, the center height tolerance is +0.02mm, the equal height difference is ≤0.006mm, the straightness is <0.02mm, the preload is stably maintained at 0.8N, and the surface roughness remains at ≤0.005mm. These stringent standards, combined with the excellent heat treatment properties of S55C steel, endow the guideways with high precision and stability after countless polishing processes, ensuring smoother and more reliable equipment operation.

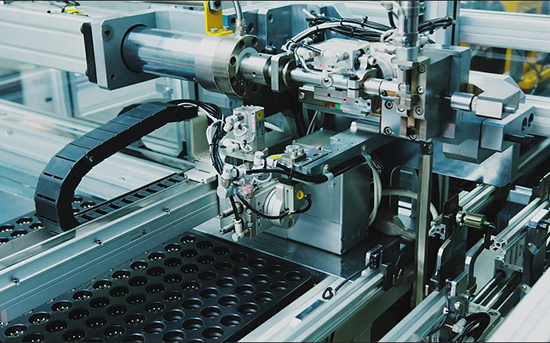

Thanks to this relentless pursuit of craftsmanship, PYG linear guideways are widely applied in high-end fields such as CNC machine tools, semiconductor manufacturing, and medical equipment, becoming a crucial force in promoting industrial automation.

Post time: May-27-2025