"Precision Code" of the Machine Tool Family: Evolution of Linear Guideways from Traditional to Intelligent

The machine tool family has a wide variety, which can be divided into dozens of types such as lathes, milling machines, grinding machines, boring machines according to processing methods. Different machine types have significantly different requirements for linear guideways:

Ordinary Lathes: As basic equipment for metal processing, the linear guideways between the carriage and the bed need to balance rigidity and wear resistance. Traditional sliding guideways achieve stable feeding under low-speed conditions through the combination of cast iron and Babbitt metal. However, modern economical lathes have generally adopted steel-inserted guideways. Through quenching treatment, the surface hardness is increased to HRC58-62, and the service life is extended by more than 3 times.

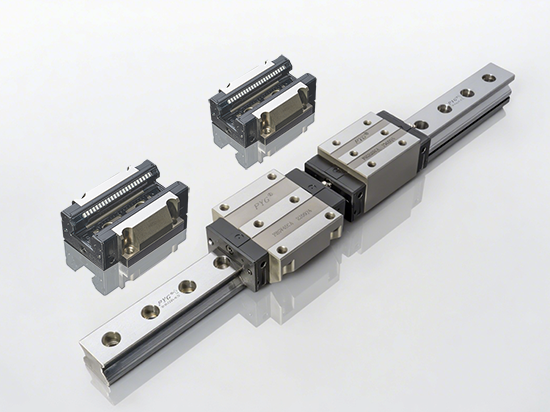

CNC Milling Machines: Facing the complex trajectories of 3D surface machining, linear guideways must have high-precision positioning capabilities. Rolling linear guideways have become the mainstream choice. The point contact design between their balls and raceways reduces the friction coefficient to 0.001-0.002. With a preloading device, they can achieve a repeat positioning accuracy of ±0.001mm, meeting the strict requirement of surface finish Ra0.8μm in mold processing.

Precision Grinding Machines: In ultra-precision machining scenarios where the grinding accuracy reaches 0.0001mm, hydrostatic linear guideways show unique advantages. They support moving parts through an oil film or air film to achieve "zero-contact" operation, completely eliminating mechanical wear. In the precision grinding of aero-engine blades, they can stably maintain micron-level shape tolerances.

Linear Guideway Technology: The "Decisive Factor" for Machine Tool Performance

The core role of linear guideways in machine tools is reflected in three dimensions:Guiding Accuracy determines the machining datum. In horizontal machining centers, for every 0.01mm/m increase in the parallelism error of the Y-axis linear guideway, the perpendicularity deviation of the workpiece end face will double. The linear guide system using dual-axis linkage error compensation technology can control such errors within 0.002mm/m, ensuring the hole system position accuracy of large box-type parts.

Load-Bearing Capacity affects the processing range. The linear guideways of heavy floor-type boring and milling machines need to bear the weight of workpieces weighing dozens of tons. Rectangular linear guideways, through widening the contact surface (up to 800mm in width) and quenching treatment, can achieve a load-bearing capacity of 100kN per meter of guideway, meeting the boring processing of large parts such as wind power flanges.

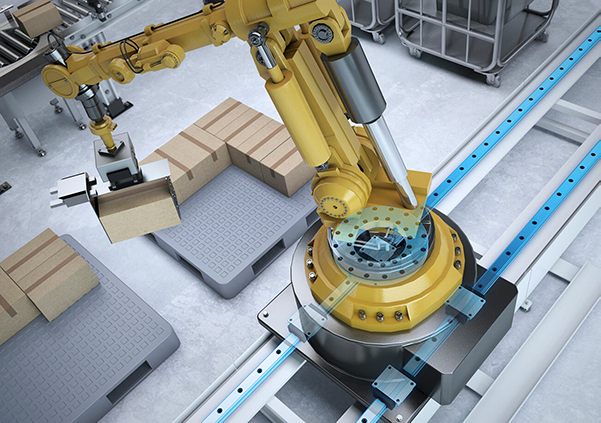

Dynamic Response is related to production efficiency. The linear guideway system of high-speed gantry milling machines is directly driven by linear motors, combined with the low inertia characteristics of rolling guideways, which can achieve a rapid traverse speed of 60m/min and an acceleration of 1g, increasing the rough machining efficiency of mold cavities by more than 40%.

Post time: Aug-21-2025