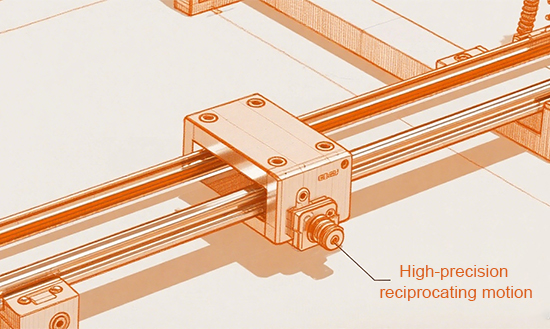

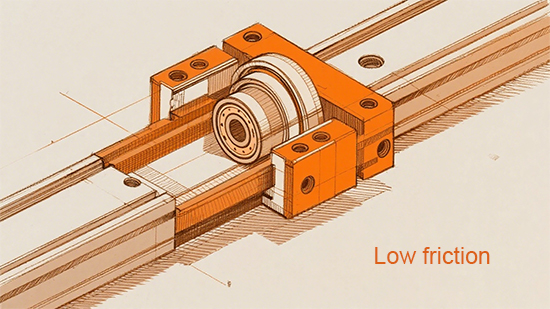

From a structural perspective, a linear guide consists of a guide rail and a slider. The design of rolling steel balls inside the slider allows it to move extremely smoothly along the guide rail. This structure brings multiple advantages: first, the friction coefficient is small, which can reduce energy consumption during movement, making the 3D printer more energy-efficient during operation; second, the operating noise is low, reducing unnecessary noise interference in the working environment; third, it has a long service life and can adapt to the scene of 3D printers working continuously for a long time. Compared with traditional sliding guides, linear guides have higher positioning accuracy and repeat positioning accuracy, which can better meet the needs of 3D printers for precise operation and ensure long-term stable operation of the equipment.

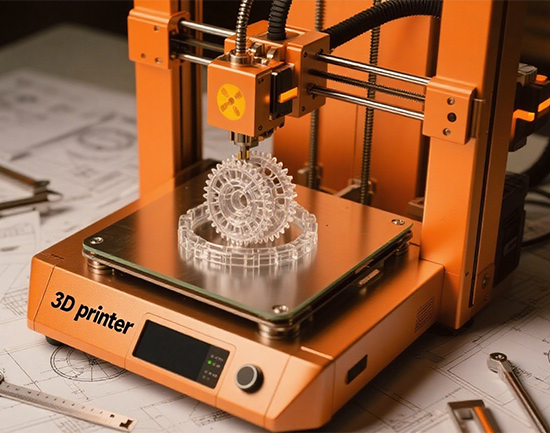

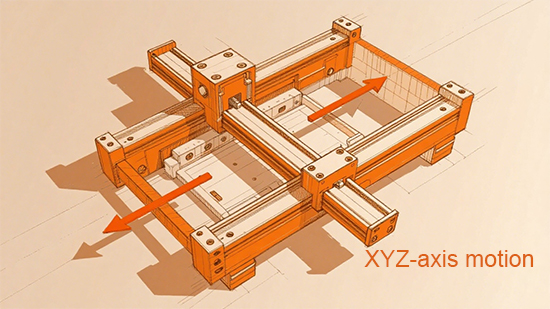

During the 3D printing process, the nozzle needs to move flexibly and quickly in the X, Y, and Z axes to precisely control the stacking position and shape of materials. The linear guide plays a key role in this process, ensuring that each movement of the nozzle is accurate. This not only makes the details of the printed model clearer and the lines more regular but also minimizes printing errors, ensuring the dimensional accuracy and structural stability of the model. At the same time, the high-rigidity structure of the linear guide can withstand the inertial force generated by the nozzle during high-speed movement, avoiding shaking or vibration during equipment operation, thereby further improving printing quality.

The maintenance of linear guides is also relatively simple. Regular cleaning and lubrication can effectively extend their service life and maintain a good operating state. This feature is particularly important for 3D printers that need to print large models continuously for a long time, as it can reduce downtime caused by maintenance and improve overall printing efficiency.

The linear guides we provide have the significant advantages of high precision and long service life, and can directly replace products of well-known brands such as THK and HIWIN, especially suitable for equipment with strict precision requirements such as 3D printers. If you need detailed cooperation plans and product quotations, please feel free to contact us, and we will provide you with professional and thoughtful services.

Post time: Aug-14-2025