Precision is crucial in the field of linear motion control. Industries such as manufacturing, robotics and automation rely heavily on precise movements to achieve desired results. Linear guides play a vital role in achieving smooth, accurate movement, ensuring optimal performance. An important factor to consider when choosing a linear guide is its E-value. But what exactly is the E-value of a linear waveguide, and why is it important? I believe that people who are not very familiar with guideways are very confused about this, so today PYG will explore this concept in more depth and explain its importance in linear motion control.

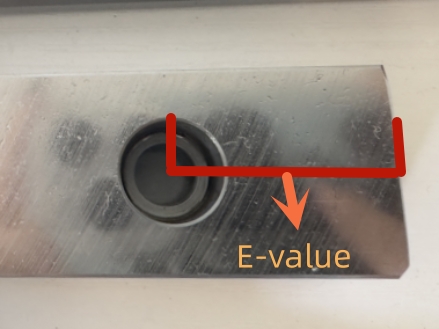

Define the E-value:

Simply put, the E-value of a linear guide is a measure of its efficiency and ability to provide precise linear motion. It represents the ability of the guider to withstand external forces such as load and acceleration. The higher the E-value, the better the performance and accuracy of the linear guide.

The meaning of E-value:

Accuracy and repeatable linear motion are crucial in related industries, and even a slight deviation can cause some non-negligible damage to the application equipment. The E-value provides engineers and designers with valuable information about the ability of linear guides to maintain accuracy under different operating conditions. It helps determine the best linear guide for a particular application, ensuring the highest level of accuracy and performance.

Factors affecting the E-value:

The E-value of a linear guide is influenced by several factors, including design, material, and manufacturing quality. The type of rolling element used (eg ball or roller bearings) also affects the E-value. In addition, factors such as lubrication, load capacity and speed will also directly affect the E-value and overall performance of the linear guide.

Precautions for choosing linear guide rails:

When choosing a linear guide, the E-value must be accurately measured along with other important factors such as load capacity, stiffness and accuracy requirements. The intended application must be carefully analyzed to determine the necessary specifications for linear guides. Whether it's high-speed applications that require fast response times or heavy-duty tasks with increased loads, choosing the right end distance can give your application the best performance.

If there is any qusetions,please contact us for detail,and our professional customer service will reply soon.

Post time: Aug-09-2023