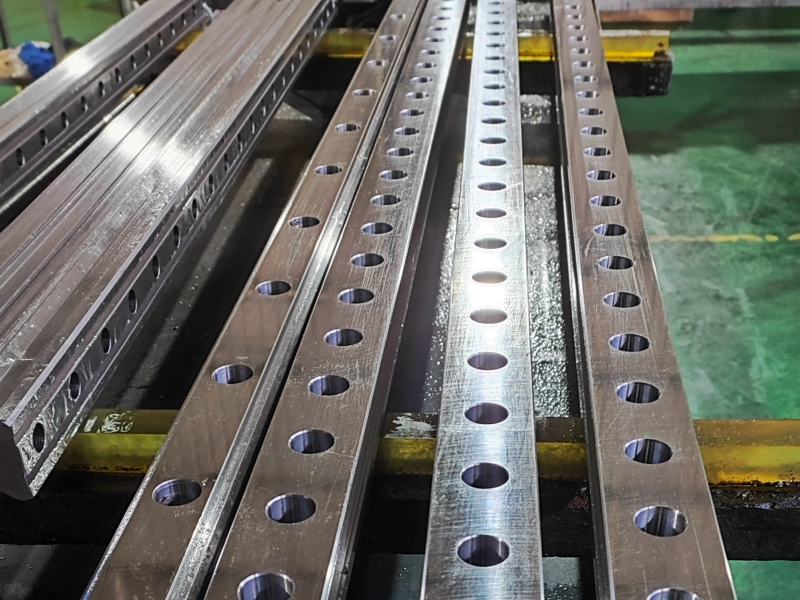

A common problem that may occur with linear guides in PYG today is increased thrust and tension. Understand the reasons behind this problem to ensure the efficient operation of the linear guide to the equipment.

One of the main reasons for the increase in push-pull force of Linear Motion Guideways is wear. Over time, components of linear guides, such as bearings and rails, wear out due to friction and repeated use. As a result, the overall friction in the system increases, resulting in greater push and pull forces required to move the load.

Another factor causing increased push and pull forces is pollution. Dust, debris, and other contaminants can penetrate linear guide systems, causing increased friction and drag. Regular maintenance and cleaning of linear guide way components is essential to prevent the build-up of contaminants and minimize the impact on push and pull forces.

Of course, improper lubrication can also lead to excessive thrust and tension in the linear guide system. Insufficient lubrication can lead to increased friction on the guide rail, which leads to increased resistance during movement. Manufacturer's lubrication guidelines must be followed, and linear guide parts must be properly lubricated to minimize push and pull.

In some cases, misalignment or improper installation of linear guide components can also cause increased push and pull forces. Misaligned rails or uneven bearing distribution can cause uneven loading and increase resistance during movement. Proper installation and alignment of CNC Machined Slide Guide components is critical to maintaining optimal performance and minimizing push and pull forces.

Therefore, it is necessary to understand the causes of the increase in thrust and tension of linear guides for troubleshooting and maintaining efficient operation. By addressing factors such as wear, contamination, lubrication and alignment, the impact on thrust and pull forces can be minimized to ensure smooth, precise movement of the linear guide system. Of course, if you have unclear questions, you can contact us, we will reply to your message as soon as possible.

Post time: Jan-16-2024