Ku-automation yezimboni, imihlahlandlela eqondile idlala indima ebalulekile ekuqinisekiseni ukunyakaza komugqa okushelelayo nokunembile.Lezi zingxenye ezibalulekile zisetshenziswa ezimbonini eziningi ezahlukahlukene, kusukela kwezokukhiqiza kuye kwezamarobhothi kanye ne-aerospace.Ukwazi izigaba ezijwayelekile zemihlahlandlela yezimboni kubalulekile konjiniyela, abaklami nanoma yimuphi umsebenzisi ohilelekile emishinini yezimboni.Kodwa-ke, ngikholelwa ukuthi abanye abantu basenokungabaza mayelana neziqondiso zomugqa futhi abaqondi ukuhlukaniswa kweziqondiso, ngakho-ke namuhla i-PYG izokunikeza incazelo enemininingwane.

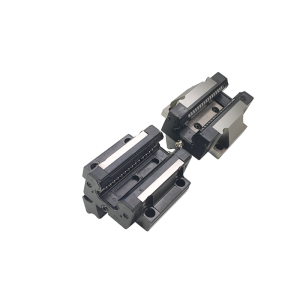

1. Umhlahlandlela womugqa onebhola:

Ibhola eliphethe imihlahlandlela eqondileziwuhlobo olusetshenziswa kakhulu ngenxa yomthamo wazo omkhulu womthwalo kanye nokunyakaza okushelelayo.Aqukethe izingxenye ezimbili eziyinhloko: amathrekhi nezinqola.Inqola isebenzisa ama-bearings amabhola ajikelezayo agingqika kumareyili ukuze aqinisekise ukunyakaza okungaguquki.Le mihlahlandlela ilungele izinhlelo zokusebenza ezidinga ukunemba okuphezulu nohambo olude, njengamathuluzi omshini we-CNC, amasistimu okusika i-laser, kanye nokukhiqizwa kwe-semiconductor.

2. Igayidi yomugqa werola:

Idizayinelwe imithwalo esindayo kanye nezindawo ezinokhahlo,roller linear guidessebenzisa ama-cylindrical rollers esikhundleni samabhola.Lokhu kulungiselelwa kuthuthukisa umthamo wokulayisha futhi kunikeza ukumelana okungcono nokungcola njengothuli nemfucumfucu.Ama-roller guide rails avame ukusetshenziswa emishinini yezimboni efana ne-heavy duty conveyors, izinto zokuphatha izinto kanye nezinhlelo zokusebenza zangaphandle.

3. Qondisa umhlahlandlela womugqa kuphela:

Iziqondiso zolayini eziqondisayo kuphela, ezaziwa nangokuthi iziqondiso zephrofayela, zisebenzisa izinsimbi eziqondisayo ukuze ziqondise ukunyakaza kwekalishi.Lo mklamo uhlinzeka ngokuqina okuphezulu kanye nokuqina, okuwenza ulungele izinhlelo zokusebenza ezidinga ukunemba okuphezulu, ukuphindaphinda, kanye nokumelana namandla e-torsional.Imihlahlandlela yomugqa womhlahlandlela kuphela isetshenziswa kakhulu kumathuluzi emishini, amarobhothi ezimboni, namanye amasistimu okunyakaza anembayo.

4. Isitimela somugqa esingaqondisiwe:

Imihlahlandlela yomugqa engenamihlahlandlela incike kumzila wesitimela owodwa ongathwala imithwalo ye-radial ne-lateral.Idizayini yayo elula kodwa eqinile iyenza ihambisane nezinhlobonhlobo zezinhlelo zokusebenza zezimboni, okuhlanganisa imishini yokupakisha, izinhlelo zokunyathelisa kanye nemishini yezokwelapha.Ngenxa yokuguquguquka kwayo, umhlahlandlela womugqa ongenamhlahlandlela ungashintshwa kalula ukuze ube nezimo ezihlukene zokufaka.

Imihlahlandlela yomugqa wezimboni iyisisekelo sentuthuko eminingi yesimanje yobuchwepheshe ukuze kuzuzwe ukunyakaza komugqa okubushelelezi, okunembile kuzimboni ezihlukahlukene.Ngokwazi ukuhlukaniswa okuvamile kwale mihlahlandlela, ochwepheshe bangakhetha uhlobo olufanele lwezidingo zabo zohlelo lokusebenza.Noma ngabe ngeyeziqondiso eziphethe ibhola ezinembayo noma iziqondiso zamarola ezisindayo, ukuhlukaniswa ngakunye kunezinzuzo zako ezihlukile.Ukuqinisekisa ukuthi i-automation yezimboni ephumelelayo iqala ngokukhetha umhlahlandlela oqondile womugqa ongathinta kakhulu ukusebenza kahle, ukusebenza kahle nempilo yemishini.Ngicela, uma ungayiqondi le ncazelo othintana nayeisevisi yethu yamakhasimende, isevisi yamakhasimende izokwenzela incazelo enemininingwane.

Isikhathi sokuthumela: Aug-11-2023