Emkhakheni wokukhiqiza okuzenzakalelayo kanye nokunemba, uhlobo lwebholaumhlahlandlela womugqaujantshi ufana nokhiye ophansi kodwa obalulekile "iqhawe elingaculwa". Ngokusebenza kwayo okuvelele, ibeka isisekelo esiqinile sokusebenza okunembile nokuzinzile kwemishini ehlukahlukene.

I-All-round Dust Prevention, Ukuvikela I-Core of Precision Transmission

Idizayini yokuvikela uthuli eyindilinga yonkeuhlobo lwebholai-linear guide ujantshi iwumugqa obalulekile wokuzivikela ukuze kuqinisekiswe ukusebenza kwayo okuzinzile kwesikhathi eside. Emseleni lapho kuxhunywe khona isitimela esiqondisayo nesilayida, kwakhiwa ama-scrapers angangenwa uthuli aphezulu nemichilo yokuvala, futhi kanye nesakhiwo sangaphandle esivikela uthuli esinamabhlogo amabili, kwakhiwa isistimu yokuvikela uthuli engu-360° efile-engela-free. Kungakhathaliseki ukuthi uthuli olucolekile endaweni yokukhiqiza noma ukungcola kwezinhlayiyana ngaphansi kwezimo zokusebenza eziyinkimbinkimbi, kunzima ukuhlasela ingaphakathi likajantshi wesitimela. Lo mklamo ungakugwema ngokuphumelelayo ukuguga nokuphazamiseka kothuli ezingxenyeni ezinembayo njengamabhola nemigwaqo yesitimela eqondisayo, ukuze ujantshi oqondisayo uhlale ugcina ukunemba okuhle nokushelela, futhi andise impilo yesevisi. Ilungele ikakhulukazi izimo zezimboni ezinothuli olwengeziwe, njengeamadivaysi e-automationukusekela imishini yokwenza izinkuni kanye nemishini yezimayini.

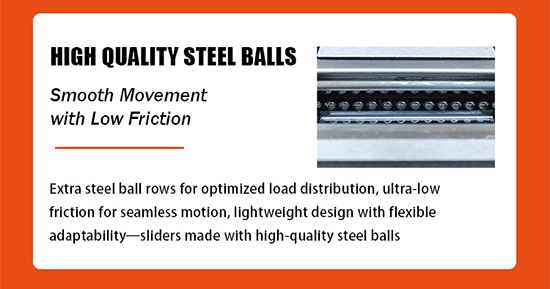

Amabhola Ensimbi Asezingeni Eliphezulu, Ukufeza Ukuhamba Okushelelayo Nokunyakaza Okuphansi

Amabhola ensimbi asezingeni eliphezulu eliwasebenzisayo yizici ezibalulekile ukuze kuzuzwe bushelelezi futhiukunyakaza kwe-low-friction. Imigqa yebhola yensimbi emisiwe ngokwengeziwe ithuthukiswa ukuze kuzuzwe ukusatshalaliswa okufanayo kwemithwalo, ukuze ujantshi oqondisayo ukwazi ukugcina isimo sokucindezeleka esizinzile lapho sithwala imithwalo ngezindlela ezihlukahlukene nosayizi. Ngesikhathi esifanayo, umzila wesitimela uthatha umklamo wesakhiwo ongasindi futhi oguquguqukayo, futhi izici zokungqubuzana okuphansi kakhulu phakathi kwamabhola ensimbi kanye nemigwaqo yomjaho zenza isilayidi sizizwe singenakho ukumelana lapho sinyakaza. Lesi sici sivumela okokusebenza ukuthi kuhambe kahle njengamafu agelezayo namanzi ngesikhathi sokusebenza, kungakhathaliseki ukuthi ukunyakaza okuhle kwesivinini esiphezulu noma ukunyakaza okuhle kwesivinini esiphansi, okuthuthukisa kakhulu ukusebenza kahle kokukhiqiza kanye nokunemba kokucubungula. Amasistimu okuphakelayo amathuluzi omshini wokunemba, okokusebenza kwengxenye ye-elekthronikhi, njll. konke kuyazuza kulesi sici.

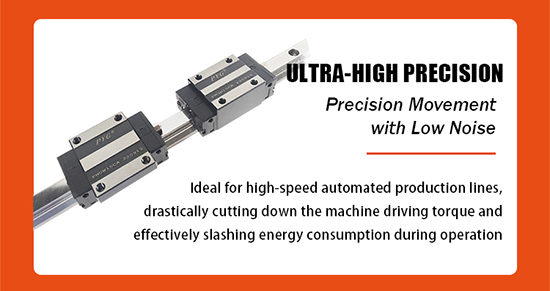

Ukunemba okuphezulu kakhulu, Kwenza Umsindo Ophansi kanye Nokukhiqiza Okuphumelelayo

Iukunemba okuphezulu kakhuluukusebenza kokunyakaza kwesitimela somugqa wohlobo lwebhola kuboniswa ngokugcwele emigqeni yokukhiqiza ezenzakalelayo enesivinini esikhulu. Inganikeza okokusebenza ngezinga lemilimitha noma ukunemba ngisho nangokwengeziwe ukuze kuhlangatshezwane nezidingo zokucubungula nokuhlanganisa okunembayo okuphezulu. Ngesikhathi esifanayo, ukusebenza komsindo ophansi kwenza ulayini wokukhiqiza uvalelise emsindweni oqinile wokungqubuzana futhi kudala indawo yokukhiqiza enethezekile. Okubaluleke nakakhulu, isici sayo se-torque ephansi sinciphisa kakhulu ukusetshenziswa kwamandla lapho imishini iqhutshwa. Nakuba ukonga amandla futhi kuvikela imvelo, futhi kunciphisa ukulahleka kwemishini. Ifaneleka kakhulu izinkambu zokukhiqiza ezizenzakalelayo ezinesivinini esikhulu ezifana nokukhiqizwa kwezimoto kanye ne-3C electronics enezidingo eziqinile mayelana nesivinini, ukunemba, kanye nokusetshenziswa kwamandla.

Uhlobo lwebholaisitimela somugqa, ngezinzuzo ezinjengokuvimbela uthuli nxazonke, ukungqubuzana okushelelayo okuphansi, ukunemba okuphezulu kakhulu kanye nomsindo ophansi, isibe ingxenye eyinhloko yokudlulisela imishini eminingi enembayo nemigqa yokukhiqiza ezenzakalelayo, okugqugquzela imboni yesimanje yokukhiqiza ukuthi iye endleleni esebenza kahle nenembe kakhudlwana.

Isikhathi sokuthumela: Sep-15-2025