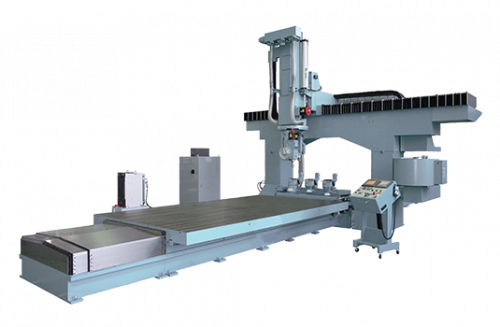

I-Linear Guides: "I-Precision Guidance Core" Yokunyakaza Kwethuluzi Lomshini

"Njengohlaka oluyisisekelo" lokunyakaza komugqa kumathuluzi omshini ozishintshayo, ukusebenza kobuchwepheshe kwemihlahlandlela yomugqa kunquma ngokuqondile umkhawulo ophezulu wokunemba komshini. Zisetshenziswa ezindaweni ezinyakazayo ezibalulekile zamathuluzi omshini futhi zamukele imiklamo ehlukene ngokusekelwe kuzimo ezithile:

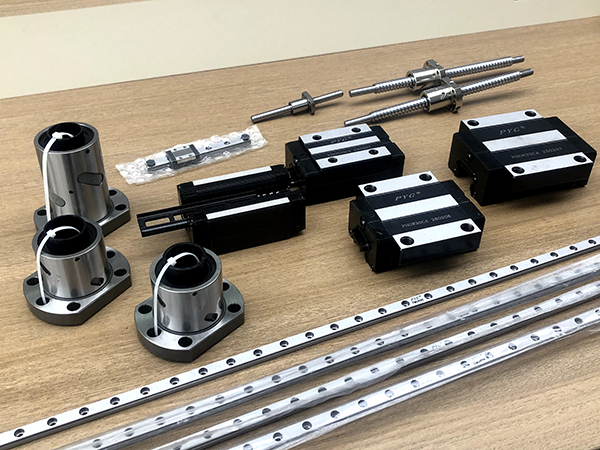

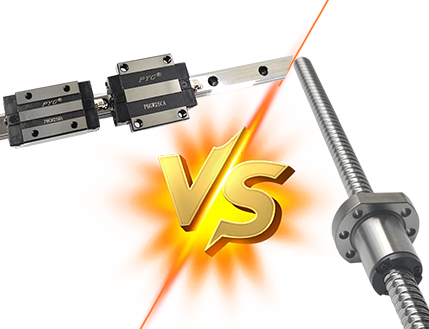

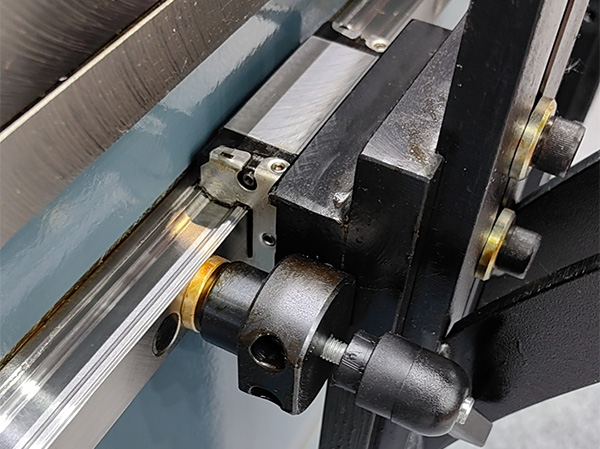

Indawo yethebula le-Workpiece:Imihlahlandlela yomugqa yomsebenzi osindayo isetshenziswa kakhulu lapha, ngesakhiwo esilinganayo samareyili angumhlahlandlela. Ama-rails angumhlahlandlela enziwe ngensimbi yokuqina okuphezulu kwe-alloy futhi agaywe ngokunemba kakhulu, okuholela ekuqineni komhlaba okungu-≤Ra0.1μm. Imvume efanelekile phakathi kwe-izinsimbi zokuqondisafuthi izilayidi zingalungiswa zibe phakathi kuka-0.002mm ngokulayisha kuqala. Lapho kucutshungulwa izingcezu zokusebenza ezinosayizi omkhulu, le mihlahlandlela ingasabalalisa umthwalo ngokulinganayo, ivimbele ukuguquguquka kwethebula lokusebenza, futhi iqinisekise ukuthi iphutha lokuqina lokunyakaza kwe-workpiece ingu-≤0.005mm/m, isusa ukuchezuka emthonjeni.

Icubungula Indawo Yokunyakaza Kwekhanda:Iziqondiso zomugqa ezincane ezinembayo eziphezulu zisetshenziswa lapha. Ingxenye ephambanayo yamareyili omhlahlandlela ngokuvamile isebenzisa ukwakheka kwamabhola anemigqa emine, engathwala imithwalo ngokulinganayo isuka eziqondisweni eziningi. Lapho ikhanda lokucubungula lidinga ukulungiswa okuhle kwemvamisa ephezulu, lingathembela ekugingqikeni okuphansi kwamabhola ukuze kufinyezwe isikhathi sokuphendula sokuma sibe phakathi kwamasekhondi angu-0.1 futhi lilawule ukunemba kokususwa endaweni yezinga le-micrometer, lisize ukufeza umphumela womshini ofana nesibuko (isb, Ra0.02μm).

Ngaphezu kwalokho, iziqondiso eziqondile zivame ukuhlonyiswa ngezinhlelo zokuzigcoba kanye nezakhiwo zokuvala uthuli. Uhlelo lokuzigcoba lujova amafutha akhethekile ngezikhathi ezithile futhi ngamanani angaguquki ukuze kuncishiswe ukuguga nokwelula impilo yesevisi; ukuvala okuvikela uthuli (njengamakhava okuvikela ohlobo lwesitho) kungavimba ama-chips ensimbi nothuli, kuvimbele ukunemba ukuthi kuthintwa ukungcola.

I-Ball Screw: "I-Precision Transmission Assistant" Yezingxenye Ezibalulekile

Izikulufu zebhola zisetshenziselwa kakhulu idrayivu yokuphakelayo yekhanda lokucubungula lethuluzi lomshini, futhi umsebenzi wazo oyinhloko ukuguqula ngokunembile ukunyakaza kwenjini kube ukunyakaza okuqondile. Ahlanganisa i-screw shaft, inati, namabhola angaphakathi. Ngokugingqika kwamabhola ngama-cyclic, ukudluliswa kwe-low-friction kuyafinyelelwa, nge-coefficient yokungqubuzana kuphela okungu-1/30 kwaleyo yezikulufu ezijwayelekile zokuslayida. Lokhu kunganciphisa ukusetshenziswa kwamandla, kunciphise ukukhiqizwa kokushisa, futhi kugwemeukunembaukukhukhuleka okubangelwa ukushintsha kwezinga lokushisa. Ngesikhathi sokucubungula, ukujula kokuphakelayo kungalawulwa ngokuya ngemiyalo, ngezinga lokuphakela elincane elingu-0.001mm, kuqinisekiswe ukuthi amapharamitha okucubungula afana ngokunembile nezidingo.

Okwamabhizinisi okukhiqiza, ikhwalithi yezingxenye eziyinhloko ezifanaUmhlahlandlela we-LMinquma ngokuqondile ukusebenza kahle kokukhiqiza. Isibonelo, embonini yezingxenye zezimoto, amathuluzi omshini asebenzisa iziqondiso ezinemba okuphezulu angakhuphula izinga lokufaneleka lokucubungula ucezu lokusebenza lube ngaphezu kuka-99.5% futhi ehlise izinga lokuhluleka kwemishini ngo-40%. Emkhakheni wokwenziwa kwemishini yezokwelapha, ngokuncika ekunembeni kweleveli ye-micrometer yamathuluzi omshini, amabhizinisi angahlangabezana nezimfuneko eziqinile zokuqedwa kwendawo kanye nobukhulu bamadivayisi asezingeni eliphezulu, okusiza ukunqamula imigoqo yobuchwepheshe ezimakethe zaphesheya kwezilwandle.

Ngokuthuthuka kwe-Industrial 4.0, imihlahlandlela eqondile ithuthuka ngendlela ehlakaniphe kakhulu. Amanye amamodeli wamathuluzi omshini wezinga eliphezulu anezinzwa ezihlanganisiwe zokushisa nokudlidliza kumahlahlandlela, angaqapha isimo sokusebenza ngesikhathi sangempela futhi alayishe idatha kuzingxenyekazi zamafu. Lezi zinhlelo zinganikeza izexwayiso zangaphambi kwesikhathi zokungajwayelekile kanye nezincomo zokulungiswa kwe-push, ukubona "ukugcinwa kokubikezela" futhi kuvimbele ukuphazamiseka kokukhiqiza okubangelwa ukwehluleka okungazelelwe, ngaleyo ndlela kunikeze ukusekelwaikhwalithi ephezulu ukuthuthukiswa kwemboni yokukhiqiza.

Isikhathi sokuthumela: Sep-02-2025