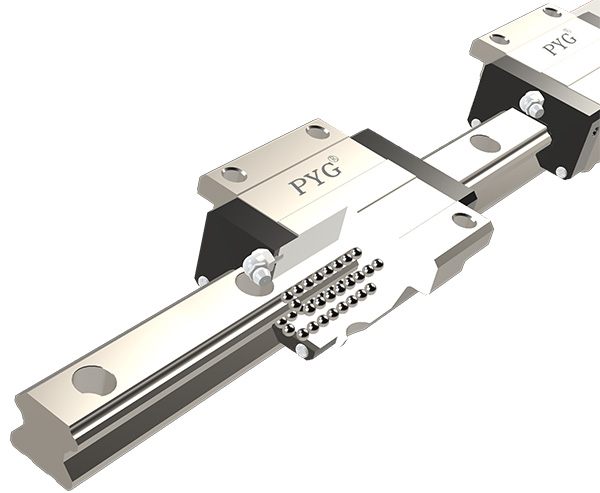

Imihlahlandlela yomugqa ye-PYG iqala ngokukhetha ngokucophelela impahla eluhlaza, ikakhulukazi ukukhetha ikhwalithi ephezuluI-S55Cinsimbi ye-carbon medium. Le nsimbi yakha isisekelo esiqinile sekhwalithi ephezulu, idume ngezici zayo ezinhle kakhulu ezihlanganisa zonke izici zobuchwepheshe kanye nokusebenza ngendlela emangalisayo.imihlahlandlela. Izisebenzi zihlola ngokucophelela ingaphezulu lemikhombandlela nezilayida, ziqinisekisa ukuthi akukho ukugqwala, ukubola, noma imigodi. Ukuqonda kwemihlahlandlela kukalwa nge-feeler gauge, okugcina ukusonta kungaphakathi kuka-≤0.15mm. Isihloli sokuqina sisetshenziselwa ukuthola ngokunembile ubulukhuni be-HRC60±2. Ama-Micrometer nama-caliper asetshenziselwa ukulawula amaphutha e-dimensional we-guideway cross-sections kanye nezilayida phakathi kuka-±0.05mm. Lezi zinqubo zisebenzisa ngokugcwele izici eziphakeme zeI-S55Cinsimbi, iqinisa isisekelo semihlahlandlela yezinga eliphezulu

Once theAma-Raw materialUkudlula ukuhlolwa, "uhambo lokuthukuthela" lwangempela luyaqala. Enqubweni yokugaya ngaphezulu, imihlahlandlela ewumugqa ibekwa ebhentshini lokusebenza, ilungiswe i-chuck kazibuthe, futhi ilinganiswe ngaphambi kokugaya indawo engezansi. Ubukhulu obungaphezulu buncishisiwe ukuze bufike ku-≤0.005mm, kuzuza ukunemba okufana nesibuko. Ngaleso sikhathi, izilayidi zigaywa ngokunemba kwezingxenye zazo eziphambanayo emshinini wokugaya, ngokubekezelela kwe-angular okulawulwa ngokuqinile ngaphakathi kuka-±0.03mm, okuqinisekisa ukuhambisana okunembayo nemihlahlandlela.

Esigabeni esibucayi se-guideway kanye nokugaya izilayidi,I-PYGisebenzisa imishini yokugaya eyisipesheli ukuze igaye imizila yomjaho enezinhlangothi ezintathu zemikhombandlela. Ukubekezelela ububanzi bemigwaqo yomjaho kulawulwa ngaphakathi kuka ± 0.002mm, ukubekezelelana kokuphakama kwesikhungo kungu-+0.02mm, umehluko olinganayo wokuphakama ngu-≤0.006mm, ukuqondisa kungu-<0.02mm, ukulayisha kuqala kugcinwa ngokuzinzile ku-0.8N, futhi ubulukhuni bobuso buhlala ku-≤0.005mm. Lawa mazinga aqinile, ahlanganiswe nezici ezinhle kakhulu zokwelashwa kokushisa kwensimbi ye-S55C, anikeza imihlahlandlela ukunemba okuphezulu nokuzinza ngemva kwezinqubo zokupholisha ezingenakubalwa, okuqinisekisa ukusebenza kahle nokuthembeke kakhudlwana kwempahla.

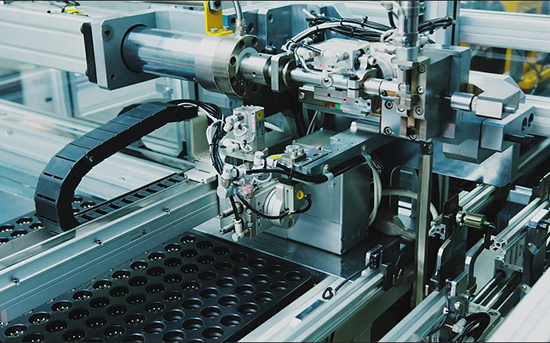

Ngenxa yalokhu kuphishekela ubuciko obungapheli, imihlahlandlela eqondile ye-PYG isetshenziswa kabanzi ekugcineni okuphezulu.amasimunjengamathuluzi omshini we-CNC, ukukhiqizwa kwe-semiconductor, kanye nemishini yezokwelapha, okuba amandla abalulekile ekukhuthazeni okuzenzakalelayo kwezimboni.

Isikhathi sokuthumela: May-27-2025