"Ikhodi Enembayo" Yomndeni Wethuluzi Lomshini: Ukuvela kweLinear Guidewayskusukela koweNdabuko kuya ku-Intelligent

Umndeni wamathuluzi womshini unezinhlobonhlobo eziningi, ezingahlukaniswa zibe inqwaba yezinhlobo ezinjengama-lathes, imishini yokugaya, imishini yokugaya, imishini eyisicefe ngokwezindlela zokucubungula. Izinhlobo zemishini ezihlukene zinezidingo ezihluke kakhulu zemihlahlandlela ewumugqa:

Ama-Lathes Ajwayelekile: Njengempahla eyisisekelo yokucubungula insimbi, imihlahlandlela eqondile phakathi kwekalishi nombhede idinga ukulinganisa ukuqina nokumelana nokugqoka. Imihlahlandlela evamile yokushelela izuza ukuphakelwa okuzinzile ngaphansi kwezimo ezinesivinini esiphansi ngokuhlanganiswa kwe-cast iron ne-Babbitt metal. Kodwa-ke, ama-lathes ezomnotho wesimanje ngokuvamile asebenzisa imihlahlandlela efakwe ngensimbi. Ngokwelashwa kokucisha, ubulukhuni bobuso bukhuphuka bufinyelele ku-HRC58-62, futhi impilo yesevisi inwetshwa izikhathi ezingaphezu kwezingu-3.

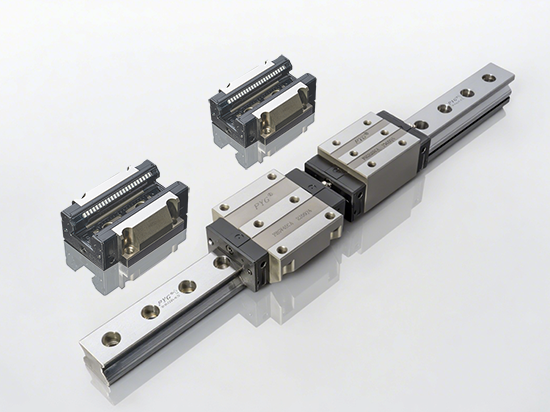

Imishini Yokugaya ye-CNC: Ibhekene nemizila eyinkimbinkimbi ye-3D surface machining, imihlahlandlela eqondile kufanele ibe nayo.ukunemba okuphezuluamakhono okubeka. Imihlahlandlela elandelanayo egingqikayo isiphenduke inketho evamile. Idizayini yephoyinti yokuxhumana phakathi kwamabhola awo nemigwaqo yomjaho yehlisa i-coefficient yokushayisana ibe ngu-0.001-0.002. Ngedivayisi yokulayisha kuqala, bangafinyelela ukunemba kokubeka okuphindayo okungu-±0.001mm, bahlangabezane nemfuneko eqinile yokuqedwa kwendawo engu-Ra0.8μm ekucubunguleni isikhunta.

Imishini Yokugaya Enembayo: Ezimeni zemishini enembe kakhulu lapho ukunemba kokugaya kufinyelela ku-0.0001mm, imihlahlandlela yomugqa we-hydrostatic ibonisa izinzuzo ezihlukile. Basekela izingxenye ezihambayo ngefilimu kawoyela noma ifilimu yomoya ukuze kuzuzwe ukusebenza "kokuthintwa kwe-zero", kuqede ngokuphelele ukugqokwa kwemishini. Ekugayweni okunembayo kwama-aero-injini, angakwazi ukugcina ukubekezelela komumo wezinga le-micron.

I-Linear Guideway Technology: "Isici Esinqumayo" Sokusebenza Kwethuluzi Lomshini

.

Indima eyinhloko yemihlahlandlela ewumugqa kumathuluzi omshini ibonakala ngezinhlangothi ezintathu:Ukunemba Kokuqondisa kunquma idethi yomshini. Ezikhungweni zokwenza imishini ezivundlile, njalo ngo-0.01mm/m ukukhuphuka kwephutha lokuhambisana komzila we-Y-axis womugqa, ukuchezuka kwe-perpendicularity yobuso bokuphela kocezu lokusebenza kuzophindeka kabili. Iumhlahlandlela womugqauhlelo olusebenzisa ubuchwepheshe besinxephezelo sephutha lokuxhumanisa i-dual-axis lungalawula amaphutha anjalo ngaphakathi kuka-0.002mm/m, iqinisekise ukunemba kwendawo yesistimu yezingxenye ezinkulu zohlobo lwebhokisi.

Umthamo Wokuthwala Umthwalo uthinta ububanzi bokucubungula. Imihlahlandlela ewumugqa yemishini eyisicefe esezingeni eliphansi neyokugaya idinga ukuthwala isisindo sezinto zokusebenza ezinesisindo esingamathani amaningi. Imihlahlandlela engunxande ewumugqa, ngokwandisa indawo yokuxhumana (kufika ku-800mm ububanzi) kanye nokwelashwa kokucisha, ingafinyelela umthamo wokuthwala umthwalo ongu-100kN imitha ngayinye yomzila, ukuhlangabezana nokucutshungulwa okuyisicefe kwezingxenye ezinkulu ezifana nama-flange amandla omoya.

I-Dynamic Response ihlobene nokusebenza kahle kokukhiqiza. Isistimu yomugqa womzila wemishini yokugaya i-gantry enesivinini esiphezulu ishayelwa ngokuqondile amamotho alayini, ahlanganiswe nezici eziphansi ze-inertia yemigudu eginqikayo, engafinyelela isivinini sokunqamula esisheshayo esingu-60m/min kanye nokusheshisa kwe-1g, okwandisa ukusebenza kahle komshini wemigodi yesikhunta ngaphezu kuka-40%.

Isikhathi sokuthumela: Aug-21-2025