Ishishini lokuVelisa i-Electronics: ukuThembela kwiNdibano eChanekileyo

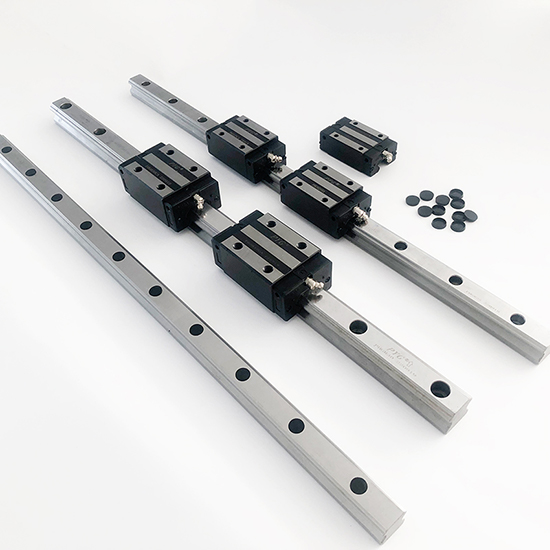

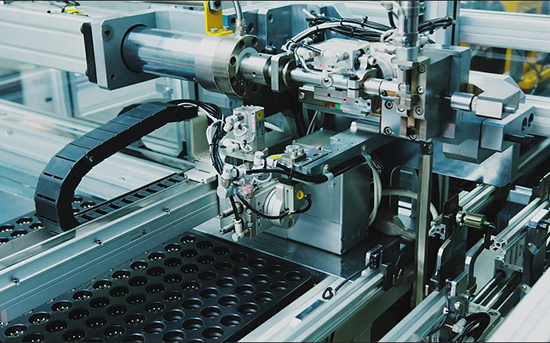

Izinto ze-elektroniki zincinci kwaye zichanekile, zivumela ukuba akukho mda wempazamo kwindibano kunye ne-welding. Kwimigca yemveliso ezenzekelayo ye-elektroniki, i-lineariireyile zokukhokelainokufezekisa ukuphindaphinda kokuchaneka kokuma kwe-±0.001mm, ukwenza i-welding ye-electronic component ichaneke ngakumbi kwaye inciphise izinga lesiphako. Kwizixhobo ezinjengoomatshini be-lithography kunye nezixhobo zokuhlola ii-wafer ezisetyenziselwa ukwenziwa kweetshiphu, ezifuna ukuchaneka komgangatho wokufuduswa kwe-nanometer, iileyili zesikhokelo ezingqameneyo zinokulawula ngokuzinzileyo ukuhamba kwamacandelo, ukuqinisekisa ukuba iinkqubo zokwenziwa kweetshiphu ziyahlangabezana nemigangatho kunye nokunceda amashishini e-elektroniki ukuba oyise imingeni echanekileyo kwimveliso yezixhobo eziphezulu.

Umzi-mveliso weSixhobo soomatshini: Undoqo woPhuculo lokuSebenza koomatshini

Izixhobo zoomatshini "ngamahashe okusebenza" kwishishini lemveliso, kwaye ukusebenza kwabo kuxhomekeke ngokupheleleyo ekuchanekeni nasekusebenzeni kakuhle. Umgangatho ophezulu wokusebenza komzila wesikhokelo unokunciphisa i-coefficient ye-friction yezixhobo zoomatshini, ukunciphisa ukunxiba koomatshini, kunye nokwandisa ubomi benkonzo yezixhobo. Xa isiphelo esiphezuluIzixhobo zoomatshini be-CNCinkqubo yamacandelo anzima, ukuqina kwawo okuphezulu kunye nokukwazi ukuphendula ngokukhawuleza kwenza ukuba oomatshini bagcine uzinzo ngexesha lokusika ngesantya esiphezulu, ukuphucula ukuchaneka kokucubungula kunye nokugqiba umphezulu. Oku kunceda izixhobo zoomatshini ziphuculwe ukusuka "kumsebenzi oqhelekileyo" ukuya "kwimveliso echanekileyo," ukuhlangabezana neemfuno zokusetyenzwa kwezinto ezintsonkothileyo kumashishini ahlukeneyo.

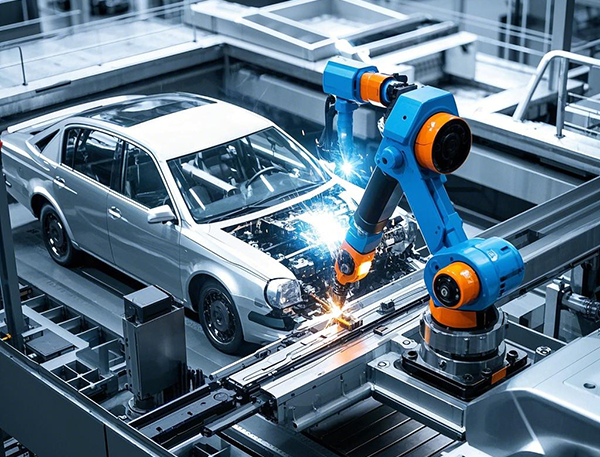

Ishishini lokuVelisa iiMoto: Ukuziqhelanisa ne-Automation kunye neMveliso yaMandla amatsha

Imigca yemveliso yeemoto ibonisa iqondo eliphezulu lokuzisebenzela, kwaye iirobhothi zokuwelda kunye neengalo zerobhothi ezidityanisiweyo zonke zixhomekeke kumzila wesikhokelo somgca wokubeka indawo echanekileyo. Imizila yesikhokelo somgca iqinisekisa ukuhambelana kwe-welding yomzimba kunye nendibano yecandelo, ukunciphisa iimpazamo. Kwizithuthi zamandla amatsha, iileyili zesikhokelo ziyakwazi ukulungelelaniswa neemeko ezifana nendibano yebhetri yePACK kunye nokuchaneka kwemoto. Abanakumelana nemithwalo enzima kuphela kodwa bakwasebenza ngokuzinzileyoimo engqongileyo entsonkothileyo, ukunceda amashishini eemoto ukuba aphucule ukusebenza kakuhle kwemveliso ngelixa ehlangabezana neemfuno ezichanekileyo ezichanekileyo zamacandelo kwiimoto zamandla amatsha.

Umzi-mveliso weZixhobo zezoNyango: UkuKhusela uDidiyo kunye nokuChaneka koNyango

Ukuchaneka kwezixhobo zonyango kuhambelana ngokuthe ngqo nempilo yezigulane, kwaye i-linear guide rails idlala indima ebalulekileyo kule ndawo. Kwi-CT scanners kunye nezixhobo ze-MRI, ziqhuba ukunyakaza okuzinzile kwamacandelo okufumanisa, ukuqinisekisa ukucaca okucacileyo kunye neenkcukacha ezichanekileyo. Iirobhothi zotyando zixhomekeke kuzo ukuze zifikelele kwinqanaba le-millimeter okanye ne-sub-millimeter-level yokulawula intshukumo, ukwenza utyando oluhlaselayo oluncinci luchaneke ngakumbi kwaye lukhuseleke ngakumbi, ukunciphisa umngcipheko wotyando, kunye nokukhuthaza uphuhliso lwezixhobo zonyango ukuya.ukuchaneka okuphezulukunye nobukrelekrele.

Ixesha lokuposa: Aug-28-2025