Izikhokelo ze-PYG zomgca ziqala ngokhetho olucokisekileyo lwemathiriyeli ekrwada, ngakumbi ukukhetha umgangatho ophezuluS55Cintsimbi yekhabhoni ephakathi. Iyaziwa ngeempawu zayo ezigqwesileyo zoomatshini kunye nobuchule, le ntsimbi ibeka isiseko esiluqilima somgangatho ophezulu.izikhokelo. Abasebenzi bahlola ngononophelo umphezulu wesikhokelo kunye nezilayidi, beqinisekisa ukuba akukho mhlwa, ukuguqulwa, okanye imingxuma. Ukuthe tye kweendlela zesikhokelo kulinganiswa nge-feeler gauge, ukugcina i-twist ngaphakathi kwe-≤0.15mm. Isivavanyi sobulukhuni sisetyenziselwa ukufikelela ngokuchanekileyo ubunzima be-HRC60±2. I-Micrometers kunye ne-calipers ziqeshwe ukulawula iimpazamo ze-dimensional of guideway cross-sections kunye nezilayidi ngaphakathi kwe-± 0.05mm. Ezi nkqubo ziphakamisa ngokupheleleyo iimpawu eziphezulu zeS55Cintsimbi, iqinisa isiseko sezikhokelo ezikumgangatho ophezulu

Kanye iiimpahla ezingekasilwaUkuphumelela ukuhlolwa, "uhambo lokuzola" lokwenyani luyaqala. Kwinkqubo yokugaya umphezulu, izikhokelo zomgca zibekwe kwi-workbench, zilungiswe yi-magnetic chuck, kwaye zilinganiswe ngaphambi kokugaya indawo engezantsi. Uburhabaxa bomphezulu buncitshiswe ukuya ku-≤0.005mm, ukuphumeza ukuchaneka okufana nesipili. Ngeli xesha, izilayidi zihamba ngokuchanekileyo ukugaya amacandelo azo anqamlezileyo kumatshini wokungqusha, ngokunyamezelwa kwe-angular kulawulwa ngokungqongqo ngaphakathi kwe-± 0.03mm, eqinisekisa ukuhambelana okuchanekileyo kunye nezikhokelo.

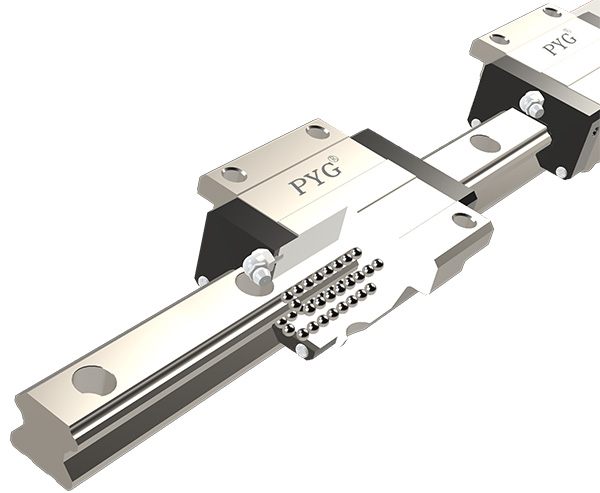

Ngexesha elibalulekileyo lesikhokelo kunye ne-slider milling,I-PYGisebenzisa oomatshini abakhethekileyo bokusila ukucola iindlela zomdyarho ezimacala mathathu kwizikhokelo. Ukunyamezela kobubanzi beendlela ze-raceways kulawulwa ngaphakathi kwe-± 0.002mm, ukunyamezela kokuphakama kweziko ku-+0.02mm, ukuhluka kobude obulinganayo ngu-≤0.006mm, ukuchaneka ngu- <0.02mm, ukulayishwa kwangaphambili kugcinwa ngokuzinzile kwi-0.8N, kunye nobunzima bomhlaba buhlala ku-≤0.005mm. Le migangatho ingqongqo, idityaniswe neempawu ezigqwesileyo zokunyanga ubushushu bentsimbi ye-S55C, inika izikhokelo ngokuchaneka okuphezulu kunye nozinzo emva kweenkqubo ezininzi zokupholisha, ukuqinisekisa ukusebenza ngokutyibilikayo nokuthembeke ngakumbi kwezixhobo.

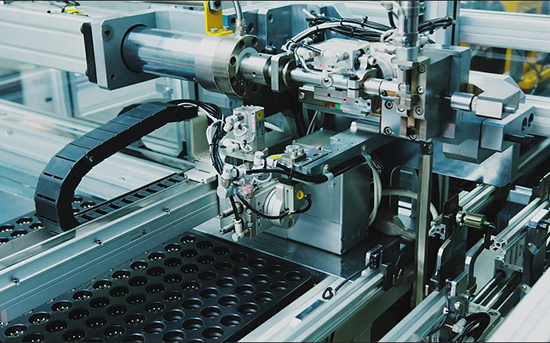

Ngombulelo kolusukelo olungayekeleliyo lobuchwephesha, izikhokelo zePYG zisetyenziswa ngokubanzi kwindawo ephezulu.amasimiezifana nezixhobo zoomatshini be-CNC, ukuveliswa kwe-semiconductor, kunye nezixhobo zonyango, zibe ngamandla abalulekileyo ekukhuthazeni ukuzenzekelayo kwemizi-mveliso.

Ixesha lokuposa: May-27-2025