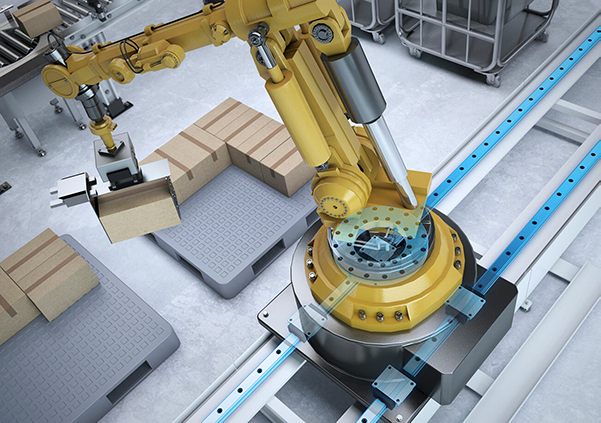

"Ikhowudi echanekileyo" yeSixhobo soShishino loSapho: I-Evolution yeLinear Guidewaysukusuka kwisiNtu ukuya kwiNgcali

Usapho lwesixhobo somatshini lunoluhlu olubanzi, olunokwahlulwa lube ziintlobo ezininzi ezinje ngeelathe, oomatshini bokugaya, oomatshini bokusila, oomatshini abakruqulayo ngokweendlela zokusebenza. Iindidi zoomatshini ezahlukeneyo zineemfuno ezahlukileyo kakhulu kwizikhokelo zemigca:

IiLathes eziqhelekileyo: Njengezixhobo ezisisiseko zokulungiswa kwesinyithi, izikhokelo zomgca phakathi kwenqwelo kunye nebhedi kufuneka zilungelelanise ukuqina kunye nokumelana nokugqoka. Izikhokelo zokutyibilika zemveli zifezekisa ukondla okuzinzile phantsi kweemeko ezinesantya esiphantsi ngokudityaniswa kwesinyithi kunye nentsimbi yeBabbitt. Nangona kunjalo, iileyile zanamhlanje zoqoqosho ziye zamkela ngokubanzi izikhokelo ezifakwe ngentsimbi. Ngokucinywa konyango, ubulukhuni bomphezulu bunyuswe ukuya kwi-HRC58-62, kwaye ubomi benkonzo bandiswa ngamaxesha angaphezu kwe-3.

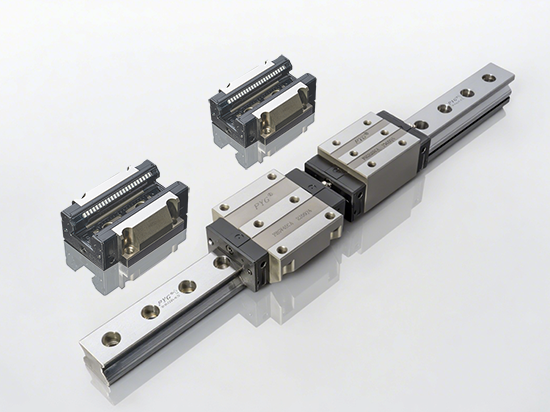

Oomatshini bokuSila be-CNC: Ukujongana neendlela ezintsonkothileyo zomatshini we-3D womphezulu, izikhokelo ezinomgca kufuneka zibe nazo.ukuchaneka okuphezuluizakhono zokubeka. Izikhokelo zomgca eziqengqelekayo ziye zaba lolona khetho luqhelekileyo. Uyilo loqhagamshelwano lwamanqaku phakathi kweebhola zabo kunye ne-raceways kunciphisa i-coefficient ye-friction kwi-0.001-0.002. Ngesixhobo sokulayisha kwangaphambili, banokufezekisa ukuchaneka kokuphindaphinda kokuma kwe-±0.001mm, ukuhlangabezana nemfuneko engqongqo yokugqiba umphezulu i-Ra0.8μm ekusetyenzweni kokungunda.

I-Precision Grinding Machines: Kwi-ultra-precision machining scenarios apho ukuchaneka kokugaya kufikelela kwi-0.0001mm, izikhokelo ze-hydrostatic linear zibonisa iinzuzo ezizodwa. Baxhasa iindawo ezihambayo ngefilimu yeoli okanye ifilimu yomoya ukuze bafezekise umsebenzi we "zero-contact", ukuphelisa ngokupheleleyo ukunxiba koomatshini. Ekusileni okuchanekileyo kwee-aero-injini ye-aero-injini, banokugcina ngokuzinzileyo ukunyamezela imilo ye-micron-level.

ITekhnoloji yeSikhokelo seLinear: "IsiGqibo seSigqibo" sokuSebenza kweSixhobo sikaMatshini

Indima ephambili yezikhokelo zemigca kwizixhobo zoomatshini ibonakaliswa kumacala amathathu: Ukuchaneka okuKhokelayo kumisela i-datum yomatshini. Kumaziko omatshini atyebileyo, rhoqo nge-0.01mm/m ukwanda kwempazamo yokunxulunyaniswa kwesikhokelo somgca we-Y-axis, ukutenxa kwe-perpendicularity yesiphelo sobuso bomsebenzi kuya kuphinda kabini. Iisikhokelo somgcaInkqubo esebenzisa itekhnoloji yembuyekezo yempazamo yonxibelelwano lwe-double-axis inokulawula ezo mpazamo ngaphakathi kwe-0.002mm/m, iqinisekisa indawo yomngxuma ukuchaneka kweendawo ezinkulu zohlobo lwebhokisi.

Umthwalo wokuthwala umthwalo uchaphazela uluhlu lokucubungula. Izikhokelo ezinqamlezileyo zomgangatho onzima wodidi oludikayo kunye noomatshini bokusila kufuneka bathwale ubunzima bezixhobo zokusebenza ezinobunzima beetoni ezininzi. Izikhokelo zomgqano ezizinxande, ngokwandisa umphezulu woqhagamshelwano (ukuya kuthi ga kwi-800mm ububanzi) kunye nokucinywa konyango, zinokufikelela umthamo wokuthwala umthwalo we-100kN ngemitha yesikhokelo, ukuhlangabezana nokusetyenzwa okukruqulayo kweendawo ezinkulu ezifana neeflange zamandla omoya.

Impendulo yeDynamic inxulumene nokusebenza kakuhle kwemveliso. Inkqubo yesikhokelo somgca we-high-speed gantry machines milling iqhutywa ngokuthe ngqo yi-motor linear, idibene ne-inertia ephantsi yeempawu ze-rolling guidelines, ezinokufikelela kwi-speed speed transverse ye-60m / min kunye nokukhawuleza kwe-1g, ukwandisa ukusebenza kakuhle kwe-machining ye-mold cavities ngaphezu kwe-40%.

Ixesha lokuposa: Aug-21-2025