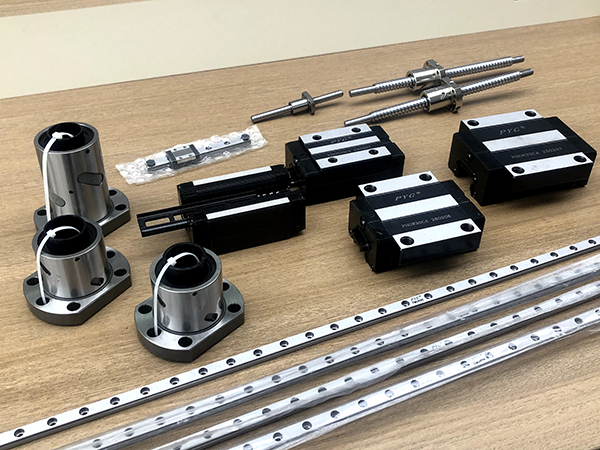

Nyob rau hauv ib lub sijhawm uas precision thiab efficiency txhais tau tias muaj kev vam meej,PYGzoo siab los qhia peb cov tiam tom ntejlinear qhia sliders-engineered rau revolutionize tswj kev txav thoob plaws kev lag luam. Tsim los rau qhov tsis sib xws, kev ua haujlwm ntev, thiab kev hloov pauv, peb cov kab ntawv qhia sliders yog cov kev daws teeb meem zoo tshaj plaws rau cov ntawv thov xws li kev kub ceev automation mus rau kev tsim khoom hnyav.

Vim li cas thiaj xaiv Peb Cov Ntawv Qhia Tawm Tawm Sliders?

1. Unmatched Precision & Stability: Peb cov kab ntawv qhia sliders yog tsim nrog cov pob los yog cov menyuam bearing tshuab, kom ntseeg tau tias du, tsis tshua muaj kev sib txhuam txav txawm tias nyob rau hauv qhov hnyav hnyav. Nrog micron-theem qhov tseeb, lawv txo qis kev vibration thiab kev ua haujlwm tsis raug, ua rau lawv zoo tagnrho rau CNC machinery, semiconductor manufacturing, thiab robotic systems qhov precision yog tsis-negotiable.

2. Muaj zog Durability: Crafted los ntawm high-qib cov ntaub ntawv xws li hardened steel los yog corrosion-resistant alloys, peb sliders tiv taus ib puag ncig hnyav, nrog rau kub kub, plua plav, thiab ya raws. Lub kaw lus tsim txuas ntxiv lub neej kev pab cuam los ntawm kev tiv thaiv cov kab mob los ntawm kev nkag mus rau cov khoom tseem ceeb, txo qis sijhawm thiab cov nqi tu.

3. Customizable Solutions: Txawm hais tias koj daim ntawv thov yuav tsum muaj cov qauv tsim kom nruj rau qhov chaw nruj, muaj peev xwm thauj khoom hnyav rau cov tshuab hnyav, lossis kev ua haujlwm ntsiag to rau cov khoom siv kho mob, peb cov kab ntawv qhia cov sliders yog tag nrho customizable. Xaiv los ntawm ntau qhov ntau thiab tsawg, qib preload, thiab lubrication xaiv kom phim koj cov kev xav tau tshwj xeeb.

4. Kev Siv Hluav Taws Xob: Los ntawm kev txo qis kev sib txhuam thiab ua kom zoo tshaj plaws ntawm kev txav mus los, peb cov sliders txo lub zog siv txog li 30% piv rau cov kab ke ib txwm muaj. Qhov no tsis yog tsuas yog txo cov nqi ua haujlwm tab sis kuj ua raws li lub hom phiaj kev ruaj ntseg thoob ntiaj teb.

Daim ntawv thov thoob plaws kev lag luam

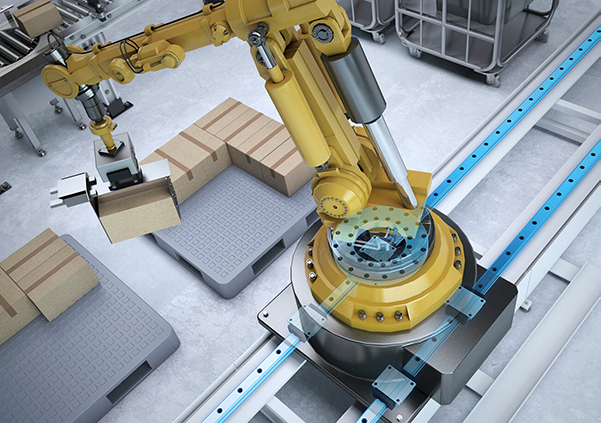

-Automation & Robotics: Txhim kho qhov ceev thiab qhov tseeb ntawm kev xaiv thiab qhov chaw, cov kab sib dhos, thiab kev sib koom tes robots.

- Cov cuab yeej siv tshuab: Ua tiav qhov tsis zoo ntawm qhov chaw tiav hauv CNC milling, sib tsoo, thiab txiav ua haujlwm.

- Cov Khoom Siv Kho Mob: Ua kom pom tseeb qhov chaw hauv cov duab kos duab, kev phais neeg hlau, thiab chav kuaj automation.

- Aerospace: Ua tau raws li cov qauv nruj rau kev ntseeg tau hauv cov khoom siv satellite.

- 3D Printing: Ua kom cov txheej txheem los ntawm txheej zoo meej hauv cov txheej txheem tsim khoom ntxiv.

Zaj Dab Neeg Txog Kev Ua Haujlwm: Elevating Automotive Manufacturing

Ib lub tuam txhab tsim tsheb loj tshaj plaws tsis ntev los no tau koom ua ke peb cov kab ntawv qhia sliders rau hauv lawv cov kab robotic. Qhov tshwm sim qhia tau hais tias 20% nce hauv kev tsim khoom nrawm thiab 40% txo qis hauv kev saib xyuas lub sijhawm, ua rau lawv ua tau raws li qhov xav tau nce EV yam tsis muaj kev cuam tshuam zoo.

Innovation ntawm Core

Ntawm PYG, peb sib koom ua ke ntau xyoo ntawm kev txawj ntse engineering nrog kev txiav-ntugR&D. Peb cov chaw tsim khoom tau lees paub ISO siv AI-tsav kev tswj xyuas kom zoo los lav txhua tus swb ua tau raws li cov qauv kev lag luam siab tshaj plaws.

Koom nrog Motion Control Revolution

Tsis txhob cia cov khoom qub dhau los txwv koj lub peev xwm. Hloov kho mus rau PYG's linear guide sliders thiab kev paub:

- ROI sai dua: Txo qis qis thiab nqi zog.

- Kev Ua Haujlwm Yav Tom Ntej: Cov kev daws teeb meem loj rau kev hloov pauv kev xav tau ntawm kev lag luam.

- Kev them nyiaj yug 24/7: Kev pabcuam thoob ntiaj teb kom koj cov haujlwm ua haujlwm tau zoo.

Post lub sij hawm: Feb-26-2025