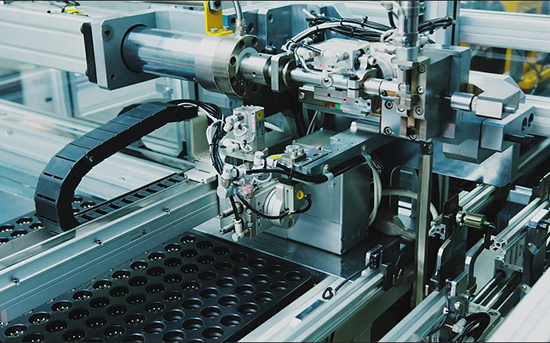

Electronics Manufacturing Industry: Reliance on Precision Assembly

Cov khoom siv hluav taws xob yog me me thiab meej, tsis muaj cov npoo rau kev ua yuam kev hauv kev sib dhos thiab vuam. Nyob rau hauv hluav taws xob automated ntau lawm kab, linearcoj railstuaj yeem ua tiav qhov rov ua qhov tseeb ntawm ± 0.001mm, ua rau cov khoom siv hluav taws xob vuam ntau dua thiab txo qis tus nqi. Rau cov khoom siv xws li lithography tshuab thiab wafer tshuaj xyuas cov cuab yeej siv hauv kev tsim cov chips, uas yuav tsum tau nanometer-theem kev hloov pauv raug, cov kab ntawv qhia kab tuaj yeem tswj tau qhov txav ntawm cov khoom, kom ntseeg tau tias cov txheej txheem tsim khoom raws li cov qauv thiab pab cov lag luam hluav taws xob kov yeej cov kev sib tw hauv cov khoom siv high-end.

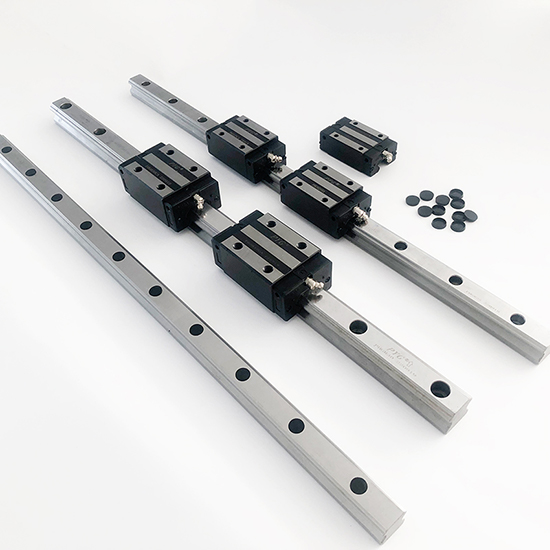

Kev Lag Luam Tshuab Kev Lag Luam: Core rau Txhim Kho Tshuab Kev Ua Haujlwm

Cov cuab yeej siv tshuab yog "cov neeg ua haujlwm ua haujlwm" ntawm kev tsim khoom, thiab lawv cov kev ua tau zoo nyob ntawm qhov tseeb thiab kev ua haujlwm zoo. High-performance linear guide rails tuaj yeem txo qhov kev sib txhuam coefficient ntawm cov cuab yeej siv tshuab, txo cov neeg kho tshuab hnav, thiab txuas ntxiv cov cuab yeej siv lub neej. Thaum high-endCNC tshuab cuab yeejtxheej txheem complex qhov chaw, lawv cov rigidity siab thiab ceev teb muaj peev xwm pab tau cov cav tov kom muaj kev ruaj ntseg thaum lub sij hawm high-ceev txiav, kev txhim kho kev precision thiab nto tiav. Qhov no pab cov cuab yeej siv tshuab hloov kho dua tshiab los ntawm "kev ua haujlwm ib txwm ua" mus rau "kev tsim khoom muaj tseeb," ua tau raws li cov kev xav tau ntawm kev ua haujlwm nyuaj ntawm ntau yam kev lag luam.

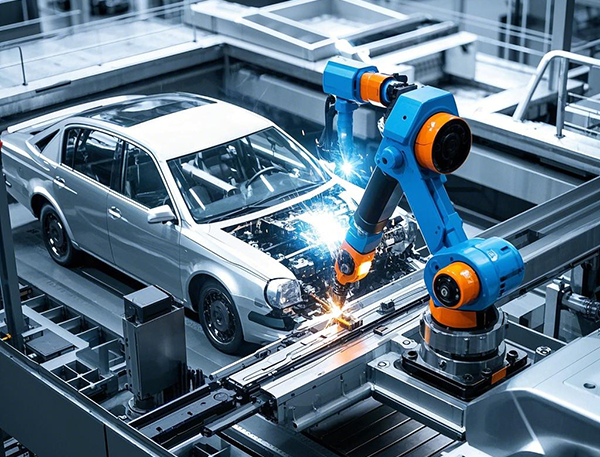

Automotive Manufacturing Industry: Kho kom haum rau Automation thiab Tshiab Zog Tsim

Automotive ntau lawm kab feature ib tug high degree ntawm automation, thiab vuam robots thiab sib dhos robotic caj npab tag nrho cia siab rau linear qhia rails rau meej qhov chaw. Cov kab ntawv qhia kev sib dhos kom ntseeg tau qhov sib xws ntawm lub cev vuam thiab cov khoom sib dhos, txo qhov yuam kev. Rau cov tsheb tshiab lub zog, cov kab ntawv qhia kab kuj tuaj yeem hloov kho rau cov xwm txheej xws li roj teeb PACK sib dhos thiab kev ua tiav lub cev muaj zog. Lawv tuaj yeem tsis tsuas yog tiv taus cov khoom hnyav tab sis kuj ua haujlwm ruaj khov hauvcomplex ib puag ncig, pab cov tuam txhab tsheb txhim kho kev tsim khoom thaum ua tau raws li qhov xav tau siab dua rau cov khoom hauv cov tsheb tshiab.

Kev Lag Luam Cov Khoom Siv Kho Mob: Kev Tiv Thaiv Kev Tshawb Fawb thiab Kev Kho Mob Precision

Lub precision ntawm cov cuab yeej kho mob yog ncaj qha cuam tshuam rau cov neeg mob kev noj qab haus huv, thiab cov kab ntawv qhia kab ua haujlwm tseem ceeb hauv daim teb no. Hauv CT scanners thiab MRI cov cuab yeej, lawv tsav lub zog ruaj khov ntawm cov khoom kuaj pom, ua kom pom tseeb thiab cov ntaub ntawv raug. Surgical robots cia siab rau lawv kom ua tiav millimeter-theem lossis txawm tias sub-millimeter-theem tswj kev txav mus los, ua kom cov kev phais me me kom meej meej thiab nyab xeeb, txo cov kev pheej hmoo ntawm kev phais, thiab txhawb kev txhim kho cov cuab yeej kho mob mus rausiab dua precisionthiab txawj ntse.

Post lub sij hawm: Aug-28-2025