Nyob rau hauv lub pursuit ntawm efficiency thiab precision nyob rau hauv industrial manufacturing, optimization ntawm kev ua tau zoo ntawmlinear qhia, raws li cov khoom tseem ceeb kis tau tus mob, ncaj qha cuam tshuam rau tag nrho kev ua haujlwm zoo ntawm cov khoom siv. PYG silent linear guide rail txais cov suab nrov txo cov tshuab thiab cov txheej txheem tsim khoom, uas txo cov suab nrov uas tsim los ntawm cov lus qhia kev tsheb nqaj hlau thaum lub sijhawm ua haujlwm.

Los ntawm ib qho tshwj xeeb pob ncig system thiab optimized qhia rail qauv, cov kev qhia tshiab rail zoo txo kev sib txhuam thiab kev sib tsoo ntawm cov khoom thiab cov kev taw qhia rail, yog li ua tau zoo heev.tsis tshua muaj suab nrov. Hauv kev siv tswv yim, qhov no ua rau qhov chaw ua haujlwm nyob ntsiag to thiab xis nyob, uas yuav pab txhim kho cov concentration thiab kev ua haujlwm ntawm cov neeg ua haujlwm.

Ntxiv rau nws cov yam ntxwv ntsiag to, PYG linear guides kuj ua tau zoo nyob rau hauv cov nqe lus ntawm smoothness. Cov chaw tsim khoom siv cov ntaub ntawv zoo thiab precision machining thev naus laus zis los xyuas kom meej tias qhov haum qhov tseeb ntawmtxoj kev tsheb ciav hlauthiab tus slider mus txog qib micrometer. Qhov kev sib koom ua haujlwm siab no ua rau cov slider txav tau yooj yim dua thiab ua haujlwm zoo ntawm txoj kev tsheb ciav hlau, uas yuav luag tsis muaj kev lag luam lossis cuam tshuam. Cov yam ntxwv ntawm kev ua haujlwm zoo no yog qhov tseem ceeb rau kev txhim kho kev ua haujlwm raug thiab ruaj khov ntawm cov cuab yeej, tshwj xeeb tshaj yog nyob rau hauv cov xwm txheej siab xws li precision machining thiab automated ntau lawm kab.

Nws yog tsim nyog hais tias cov lus qhia ntsiag to linear kuj muaj peev xwm ua tau zoo thiab ua haujlwm ntev. Los ntawm kev ua kom zoo ntawm cov qauv tsim ntawm cov lus qhia kev tsheb ciav hlau thiab cov slider, qhov chaw sib cuag thiab lub zog ntawm qhov chaw thauj khoom tau nce, ua rau cov kev taw qhia kev tsheb ciav hlau tuaj yeem tiv taus ntau dua radial thiab axial loads. Nyob rau tib lub sijhawm, kev siv ntawmsiab zoocov ntaub ntawv thiab cov txheej txheem kev kho cua sov siab heev tau txhim kho lub hardness thiab hnav tsis kam ntawm cov kev taw qhia rail, ncua nws txoj kev pab cuam lub neej.

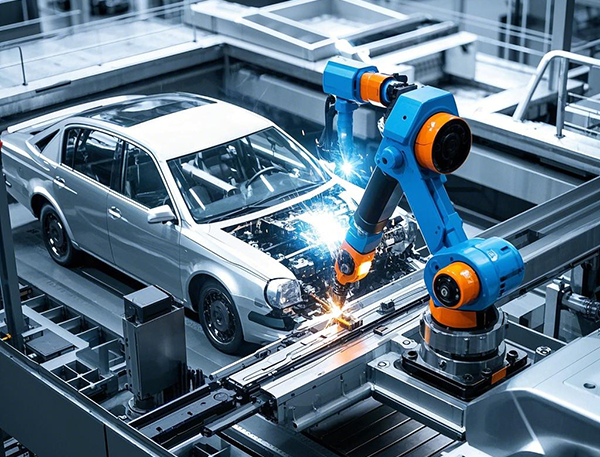

PYGntsiag to linear guidetsis tsuas yog ua tau raws li kev lag luam qhov kev thov rau high-precision thiab high-efficiency kis tau tus mob Cheebtsam, tab sis kuj coj ib tug tshiab tov rau lubindustrial manufacturing teb. Raws li cov chaw tsim khoom, cov khoom lag luam tau ua tiav hauv ntau qhov kev lag luam, suav nrog CNC tshuab cuab yeej, kev tsim hluav taws xob, tsheb sib dhos, thiab lwm yam. Cov neeg siv khoom tawm tswv yim qhia tau hais tias cov kev taw qhia tshiab rail tau ua tiav cov txiaj ntsig tseem ceeb hauv kev txhim kho cov cuab yeej ua haujlwm, txo cov suab nrov, thiab txuas ntxiv cov cuab yeej siv lub neej.

Lub sij hawm xa tuaj: Mar-19-2025