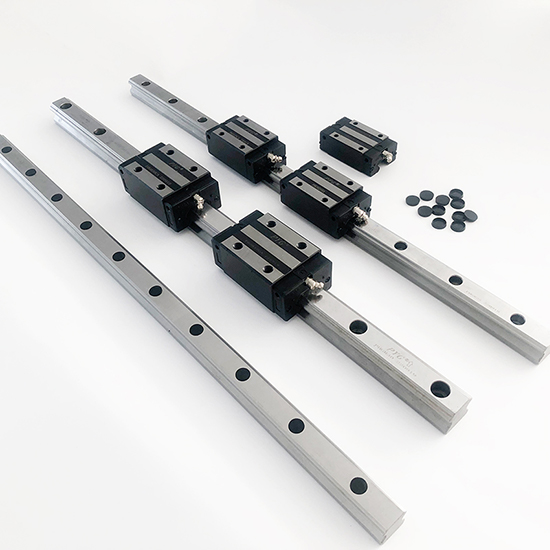

PYGkab ntawv qhiarails yog ua los ntawm kev ua tib zoo xaivS55C hlauraws li cov khoom siv raw. Cov hlau no muaj cov khoom siv zoo heev, ua rau lub hauv paus ruaj khov rau cov khoom zoo. Thaum lub sijhawm tsim khoom, nws tau dhau los ua cov txheej txheem meej, suav nrog quenching, txiav, shaping, nto tiv thaiv xeb, sib tsoo, thiab tshuaj xyuas. Cov txheej txheem quenching ho nce qhov tawv tawv ntawm cov lus qhia, txhim kho lawv cov hnav tsis kam; precision txiav thiab shaping xyuas kom meej cov khoom qhov ntev; kev kho deg los tiv thaiv xeb zoo txuas ntxiv lub neej kev pab cuam ntawm cov lus qhia, ua haujlwm ruaj khov txawm tias nyob hauv ib puag ncig hnyav; cov txheej txheem sib tsoo zoo meej yog tus yuam sij kom ua tiav ultra-siab precision. Los ntawm kev polishing zoo ntawm daim ntawv qhia kev tsheb nqaj hlau, qhov roughness ntawm qhov chaw raug txo kom qis qis, muab kev lees paub rau kev ua haujlwm siab.

nrujkev tshuaj xyuas cov txheej txheem yog kev koom ua ke thoob plaws hauv tag nrho cov txheej txheem ntau lawm. Txhua theem, los ntawm cov khoom siv raw mus rau cov khoom lag luam semi-tiav thiab thaum kawg mus rau cov khoom tiav, ua tiav ntau qhov kev tshuaj xyuas. Nws yog qhov tseeb nrog qhov kev mob siab rau qhov kev ua haujlwm zoo nkauj uas PYG linear qhia rails ua tiav ultra-siab precision, nrog rau qhov siab tshaj plaws mus los ntawm ≤ 0.003mm, deb tshaj qhov nruab nrab ntawm kev lag luam. Qhov no ua rau lawv ua tau raws li cov kev cai ntawm cov cuab yeej siv nrog cov kev xav tau siab heev, xws li high-end CNC tshuab cuab yeej thiab precision ntsuas ntsuas.

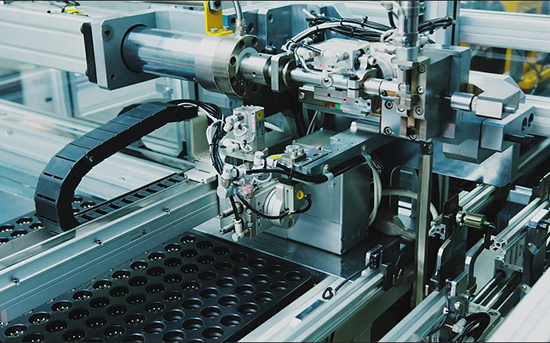

Ntxiv rau qhov siab precision, PYG linear guide rails kuj muaj qhov zoo ntawm kev ua haujlwm ntev thiab txhim khu kev qha. Txhua kauj ruam, los ntawm kev xaiv cov khoom siv mus rau kev ua tiav, tag nrho txiav txim siab txog kev ua haujlwm ntev ntawm cov khoom. Lawv tseem tuaj yeem ua haujlwm ruaj khov hauv qab hnyavua hauj lwm tej yam kev mobxws li kev thauj khoom siab thiab nquag pib-nres, txo cov khoom siv tu cov nqi thiab kev poob qis. Lawv lub peev xwm tiv thaiv plua plav siab kuj tseem zoo heev. Cov qauv tsim tshwj xeeb thiab kev tiv thaiv kev tiv thaiv tuaj yeem tiv thaiv kev nkag mus ntawm impurities xws li plua plav thiab cov khib nyiab, ua kom muaj kev ua haujlwm zoo hauv thaj chaw muaj plua plav.

Rau siab heevib puag ncigxws likub kubthiab lub tshuab nqus tsev, PYG tau tshaj tawm cov qauv tsheb ciav hlau ua los ntawm cov hlau. Tag nrho cov khoom siv hlau tsis yooj yim rau deformation ntawm qhov kub thiab txias thiab tuaj yeem ua tau raws li qhov tshwj xeeb ntawm lub tshuab nqus tsev ib puag ncig, muab cov kev daws teeb meem zoo rau kev lag luam xws li semiconductor manufacturing thiab aerospace.

Post lub sij hawm: May-13-2025