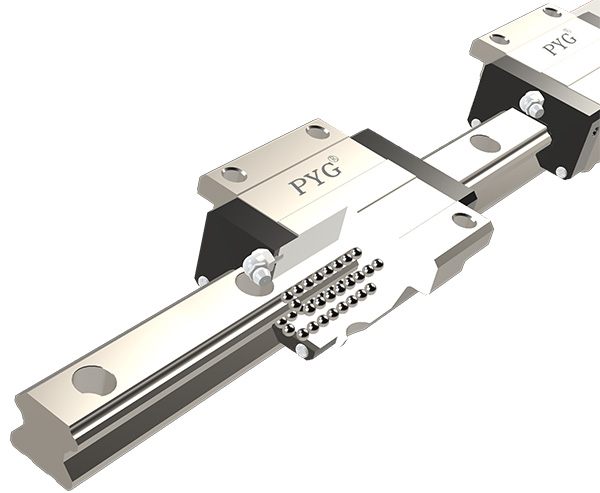

PYG linear guideways pib nrog kev xaiv raw khoom zoo, tshwj xeeb yog xaiv cov khoom zooS55 Cmedium-carbon hlau. Renowned rau nws cov khoom zoo heev txhua yam thiab machinability, cov hlau no nteg lub hauv paus ruaj khov rau cov khoom zoo.kev taw qhia. Cov neeg ua haujlwm ua tib zoo tshuaj xyuas qhov chaw ntawm cov kev taw qhia thiab cov sliders, kom tsis txhob xeb, deformation, los yog pits. Qhov ncaj ntawm txoj kev taw qhia yog ntsuas nrog lub ntsuas ntsuas, ua kom qhov sib tw tsis pub dhau ≤0.15mm. Lub hardness tester yog siv los ua kom tiav qhov hardness ntawm HRC60 ± 2. Micrometers thiab calipers yog ua haujlwm los tswj qhov tsis raug ntawm qhov kev taw qhia hla ntu thiab cov sliders hauv ± 0.05mm. Cov txheej txheem no tag nrho leverage cov yam ntxwv superior ntawmS55 Csteel, ntxiv dag zog rau lub hauv paus rau sab saum toj-tier guideways ..

Ib zaug lubraw khoomdhau kev tshuaj xyuas, qhov tseeb "kev taug kev" pib. Nyob rau hauv cov txheej txheem kev sib tsoo nto, cov txheej txheem qhia tau muab tso rau ntawm lub rooj zaum ua haujlwm, kho los ntawm cov hlau nplaum sib nqus, thiab qib ua ntej sib tsoo hauv qab. Qhov saum npoo roughness yog txo mus rau ≤0.005mm, ua tiav daim iav zoo li precision. Lub caij no, cov sliders undergo precision milling ntawm lawv cross-sections ntawm lub tshuab milling, nrog angular tolerances nruj me ntsis tswj nyob rau hauv ± 0.03mm, xyuas kom meej compatibility nrog cov kev taw qhia.

Thaum lub sij hawm tseem ceeb ntawm kev taw qhia thiab slider milling,PYGsiv cov tshuab sib tsoo tshwj xeeb los zom cov kev sib tw peb sab ntawm cov kev taw qhia. Qhov dav siab ntev ntawm txoj kev sib tw yog tswj tsis pub dhau ± 0.002mm, qhov nruab nrab qhov siab siab yog +0.02mm, qhov sib npaug qhov siab qhov sib txawv yog ≤0.006mm, qhov ncaj yog <0.02mm, preload yog ruaj khov ntawm 0.8N, thiab qhov roughness tseem nyob ntawm ≤0.005mm. Cov qauv nruj no, ua ke nrog cov khoom siv kho cua sov zoo ntawm S55C steel, muab cov kev taw qhia nrog kev ua haujlwm siab thiab ruaj khov tom qab suav tsis txheeb polishing txheej txheem, kom ntseeg tau tias cov cuab yeej siv tau yooj yim dua thiab txhim khu kev qha.

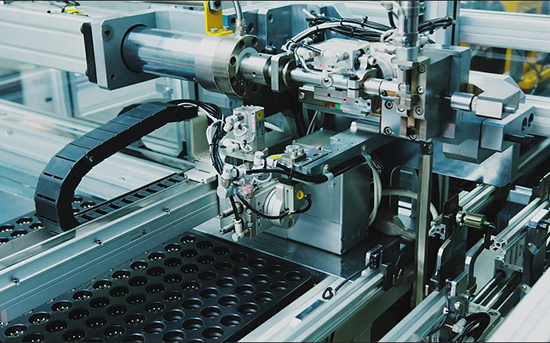

Ua tsaug rau qhov no tsis tu ncua nrhiav kev ua haujlwm zoo nkauj, PYG linear guideways tau siv dav hauv high-endtebxws li CNC tshuab cuab yeej, semiconductor manufacturing, thiab cov cuab yeej kho mob, dhau los ua lub zog tseem ceeb hauv kev txhawb kev lag luam automation.

Post lub sij hawm: May-27-2025