"Precision Code" ntawm lub tshuab cuab yeej tsev neeg: Evolution ntawmLinear Guidewayslos ntawm Traditional mus rau Intelligent

Cov cuab yeej siv tshuab tsev neeg muaj ntau yam, uas tuaj yeem muab faib ua ntau hom xws li tshuab dhos, tshuab milling, sib tsoo tshuab, tshuab tho txawv raws li kev ua haujlwm. Cov tshuab sib txawv muaj qhov sib txawv loj heev rau cov kev taw qhia linear:

Ordinary Lathes: Raws li cov cuab yeej siv yooj yim rau kev ua hlau, cov kab ntawv qhia ntawm lub tsheb thiab lub txaj yuav tsum sib npaug rigidity thiab hnav tsis kam. Cov txheej txheem zawv zawg ib txwm ua tiav kev noj zaub mov ruaj khov nyob rau hauv qis-ceev xwm txheej los ntawm kev sib xyaw ntawm cov hlau cam khwb cia thiab Babbitt hlau. Txawm li cas los xij, niaj hnub kev lag luam tshuab lathes feem ntau tau txais cov txheej txheem steel-ntxig. Los ntawm kev kho quenching, qhov tawv tawv tau nce mus rau HRC58-62, thiab kev pabcuam lub neej txuas ntxiv los ntawm ntau dua 3 zaug.

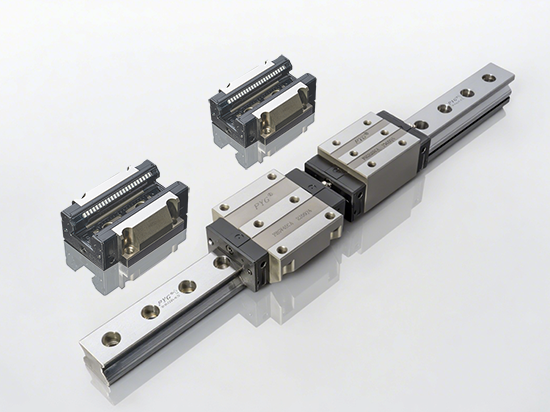

CNC Milling Tshuab: Tau ntsib txoj hauv kev nyuaj ntawm 3D nto machining, txoj kev qhia yuav tsum muajhigh-precisionpositioning peev xwm. Rolling linear guideways tau dhau los ua qhov kev xaiv tseem ceeb. Qhov taw tes sib txuas tsim ntawm lawv cov pob thiab cov kab sib tw txo cov kev sib txhuam coefficient rau 0.001-0.002. Nrog rau cov khoom siv ua ntej, lawv tuaj yeem ua tiav qhov rov ua haujlwm qhov tseeb ntawm ± 0.001mm, ua tau raws li qhov yuav tsum tau ua kom nruj ntawm qhov chaw tiav Ra0.8μm hauv kev ua pwm.

Precision Sib Tsoo Tshuab: Nyob rau hauv ultra-precision machining scenarios qhov twg qhov sib tsoo raug ncav cuag 0.0001mm, hydrostatic linear guideways qhia tshwj xeeb zoo. Lawv txhawb kev txav mus los ntawm cov yeeb yaj kiab roj lossis cov yeeb yaj kiab huab cua kom ua tiav "zero-hu" kev ua haujlwm, tshem tawm tag nrho cov khoom siv. Nyob rau hauv kev sib tsoo precision ntawm aero-engine hniav, lawv muaj peev xwm stably tuav micron-theem duab tolerances.

Linear Guideway Technology: Qhov "Decisive Factor" rau Tshuab Tool Performance

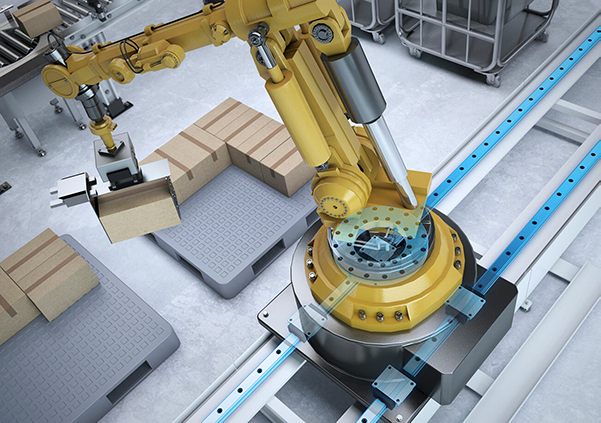

cov

Lub luag haujlwm tseem ceeb ntawm cov kev taw qhia hauv cov cuab yeej siv tshuab yog pom hauv peb qhov ntev: Kev Taw Qhia Qhov tseeb txiav txim siab qhov machining datum. Nyob rau hauv kab rov tav machining chaw, rau txhua txhua 0.01mm / m nce nyob rau hauv parallelism yuam kev ntawm Y-axis linear guideway, lub perpendicularity sib txawv ntawm lub workpiece kawg lub ntsej muag yuav ob npaug. Covkab ntawv qhiasystem siv dual-axis linkage yuam kev them nyiaj thev naus laus zis tuaj yeem tswj cov kev ua yuam kev li ntawm 0.002mm / m, kom ntseeg tau lub qhov system qhov tseeb ntawm lub thawv loj-hom qhov chaw.

Load-Bearing Capacity cuam tshuam rau kev ua haujlwm ntau. Cov txheej txheem kev qhia ntawm hnyav pem teb-hom tho txawv thiab milling tshuab yuav tsum tau dais qhov hnyav ntawm workpieces hnyav kaum ob tons. Rectangular linear guideways, los ntawm kev nthuav dav ntawm qhov chaw sib cuag (txog li 800mm hauv qhov dav) thiab quenching kev kho mob, tuaj yeem ua tiav lub peev xwm ntawm 100kN ib 'meter' ntawm kev taw qhia, ntsib kev tho txawv ntawm qhov loj xws li cua fais fab flanges.

Dynamic Response muaj feem xyuam rau kev tsim khoom. Lub linear guideway system ntawm high-ceev gantry milling tshuab yog ncaj qha tsav los ntawm linear motors, ua ke nrog cov inertia tsawg inertia yam ntxwv ntawm dov guideways, uas muaj peev xwm ua tau ib tug ceev traverse ceev ntawm 60m / min thiab ib tug acceleration ntawm 1g, nce qhov ntxhib machining efficiency ntawm pwm kab noj hniav los ntawm ntau tshaj 40%.

Post lub sij hawm: Aug-21-2025